Our sales partner SAKAKI Corporation, Osaka in Japan, has prepared this exciting and interesting application report in cooperation with its customer Nakatsugawa Packaging. It deals with the use of our LP-HFD2 laser projector to optimize the manufacturing processes in the production of high-quality corrugated board packaging. Many thanks for this great application example.

January 8, 2020; Hiroshi ITO (Mr.), Manager Production Engineering Department;

Nakatsugawa Packaging Industrial. Co., Ltd.

Short company profile of Nakatsugawa Packaging Industrial. Co., Ltd.

The company was founded on January 14, 1955 at Nakatsugawa City – Gifu Prefecture – Japan (actual Nakatsugawa factory’s premises) with initial capital 1.05 million JPY (ca. 8,400 EUR). Conducted by strong belief of the founder Mr. Etsudo OHTSUJI (first name was renamed Katsuhiro afterwards, passed away in 1988) for “packaging”, the company developed reinforced corrugated sheet “Nabiace (NB Ace)” and corrugated board pallet “Nabipallet (NB Pallet)” and has been devoting its efforts to be a corporate orientated to development/customization to satisfy the customers’ demands and reliance.

The company’s business line includes processing and sales of corrugated board sheets and boxes, reinforced corrugated sheet “Nabiace (NB Ace)” and corrugated board pallet “Nabipallet (NB Pallet)”, and design and consultation of various custom-designed packaging.

For reference, the company Nakatsugawa Packaging Industrial. Co., Ltd. Is planned to be renamed NabiAce Co., Ltd.”.

How did Nakatsugawa Packaging find the way to Z-Laser?

The company (Mr. Hiroshi ITO) knew Z-Laser 2D projector through internet.

Who has been our competitors in Nakatsugawa’s selection process?

There was no competitor to Z-Laser at the decision of employment of 2D projector. Also, Nakatsugawa Packaging should be the first and only one who employed 2D projector amongst its competitors.

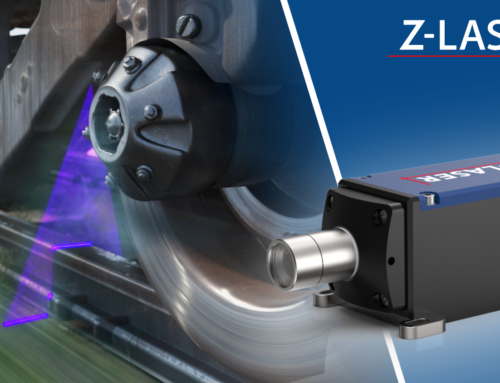

What is the main task of Z-Laser LP-HFD2 projector in the application at Nakatsugawa Packaging?

It is a positioning of different work pieces (corrugated sheets) in the process of stacking and pasting of these work pieces.

Which problem is solved by using Z-Laser LP-HFD2 projector?

In the past, in order to position different work pieces, a dedicated tool for positioning was used. It however implies huge amount of time, labor and cost to manage more than thousands of such dedicated tools. Also, the company was starting to lack the space for storage of tools, and cost for making the tools was critically increasing. If such dedicated tools are not used, it becomes necessary instead to apply “marking” by means of printing or tracing by blade on work pieces, eventually causing further work time for processing. Besides, such printing or blade tracing requires an initial cost of a few 10,000 to 100,000 JPY (ca. 200 to 2,000 EUR) per piece.

By having employed Z-Laser LP-HFD2 projector, all those problems have been solved and moreover, it noticeably reduced mistake in assembly work process, consequently the customers’ complaints.

Why did Nakatsugawa Packaging decide to use Z-Laser LP-HFD2 projector?

Since the work pieces are stacked, it was necessary to adapt to changes of projection height. It was amazing that Z-Laser 2D projector can adapt different projection height only with ZH command. Controllability by HPGL was also important as it allows easy management of the data for laser projection.

How Z-Laser LP-HFD2 projectors are implemented/controlled in workflow at Nakatsugawa Packaging?

- When a certain new packaging product is registered into company’s basic system, an HPGL is automatically created from the product information by means of ORACLE procedure and it is stored in database. For special product, HPGL is individually rectified and registered.

- At the assembly process site, the HPGL already registered in database is prepared (stand-by) by process control system at the start of assembly work. Then, the HPGL is transmitted to Z-Laser 2D projector by FTP communication and the first laser projection is done.

- Different figures are projected on work pieces depending upon its stacking height every time an operator steps on footswitch.

- Position and rotation of laser projection can be altered by tablet and the next laser projections can be done with the altered position and rotation.

Thus, the operator simply pastes the work pieces just as indicated by laser projection, without applying positioning tools as was done before.

Automatic creation of HPGL being synchronized with initial product registration was developed by ORACLE stored procedure, and control of laser projection was developed as web application by python (django). As for preparation (stand-by) of HPGL applied at assembly work process, KVS is employed as database, which allows to manage temporary change and status at processing.

What is the acceptance of the employees for Z-Laser LP-HFD2 projector?

Currently, the 2D laser projector has been applied to three assembly process lines and it has been working for about 2,000 hours in total per year. The demand (working hours of laser projection) has been increasing compared to the time when the 2D projector was introduced. The merits (benefits) to use laser projection are accordingly increasing, consequently, the area where the laser projection is applicable is expected to be widened in future.

Number of cost or time being saved by using Z-Laser LP-HFD2 projector

- Thanks to elimination of marking process by printing or blade-tracing, a big size corrugated sheet printer has become unnecessary, so the work time for 30 to 60 minutes per day in the middle process could be saves, having resulted in cost saving per month of a few 100,000 JPY (ca. 2,000 EUR) (when applied to two assembly process).

- Since the printing or blade-tracing need not be introduced, initial cost for a new packaging product could be saved for a few 10,000 to 100,000 JPY (ca. 200 to 2,000 EUR).

- Compared to the assembly work using tools, operator’s mistake has been noticeably minimized and has eventually reduced the customers’ complaints.

- No need of assembly tools and their storage shelfs has remarkably contributed to space saving in the factory.

Further product informations about the Z-LASER LP-HFD2

Note: Translation into English language of the original document created by Mr Hiroshi ITO in Japanese language is made by SAKAKI CORPORATION (es).