Geothermal heat is a renewable energy source, low in emissions and capable of assuming part of the base load in the energy mix. When drilling deep into the earth’s crust, the temperature rises by an average of about three degrees Celsius per 100 meters. However, in deep geothermal drilling the drill bits encounter different materials, including hard rock. Hard rock can only be drilled with low rates of penetration and the drill bit wears more quickly. The cost can be pro-hibitive, frequently preventing investors from going ahead with deep geother-mal projects. The Fraunhofer IPT has therefore developed a method for laser-assisted mechanical drilling of hard rock. Scientists from the Fraunhofer IPT have joined forces with partners in the “LaserJetDrilling” research project and successfully tested this technique in field trials.

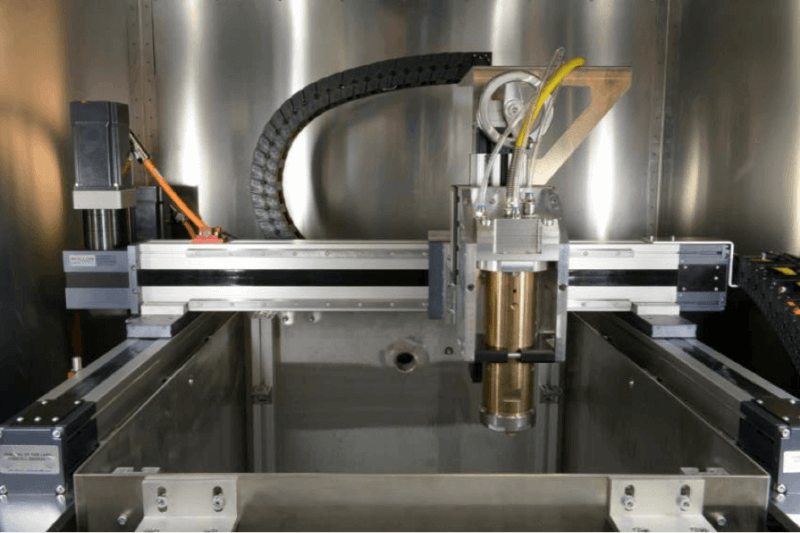

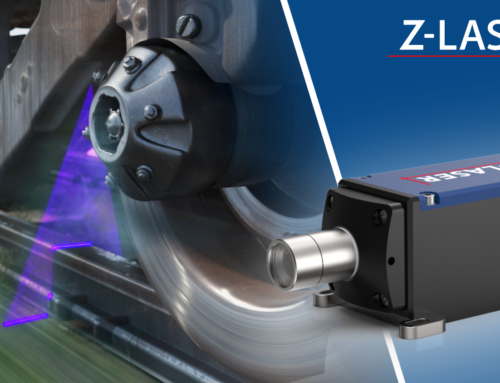

In the newly developed process, the researchers equipped the mechanical drill with a high-performance laser whose energy is guided onto the rock via a water-jet. This makes it possible to weaken the material immediately before the drilling process takes place and facilitates subsequent mechanical removal by the drilling tool. The water-jet not only guides the laser beam to the rock face, but also prevents contamination and damage of the sensitive laser optics.

In order to increase the rate of penetration of the drill bit and to preserve its cutting edge, it is necessary to introduce additional energy into the borehole. Since different and often unpredictable materials have to be processed as the drilling depth increases, the flexible adjustment of the laser output power makes it a particularly efficient tool.

Read more here: https://www.ipt.fraunhofer.de/en/Press/Pressreleases/20190214_geothermal-drilling-high-power-laser-weakens-and-fractures-hard-rock.html