Laser projectors as digital templates

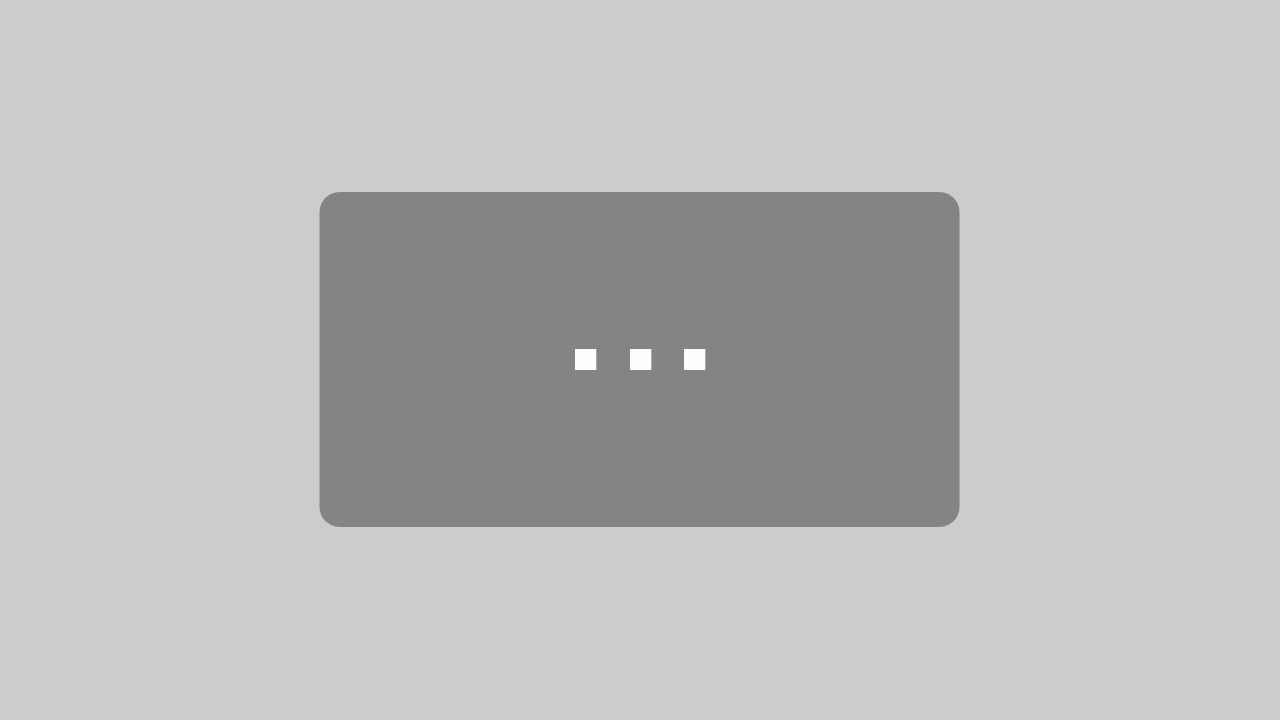

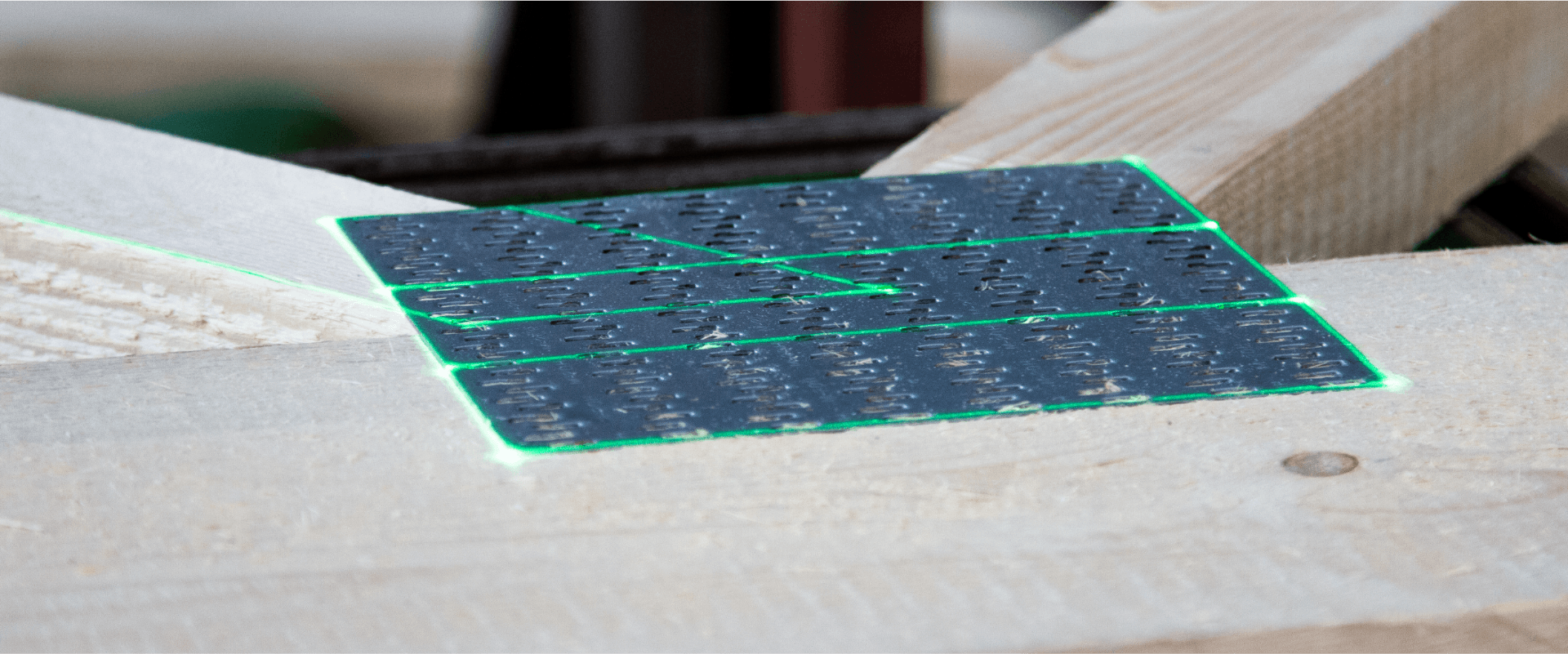

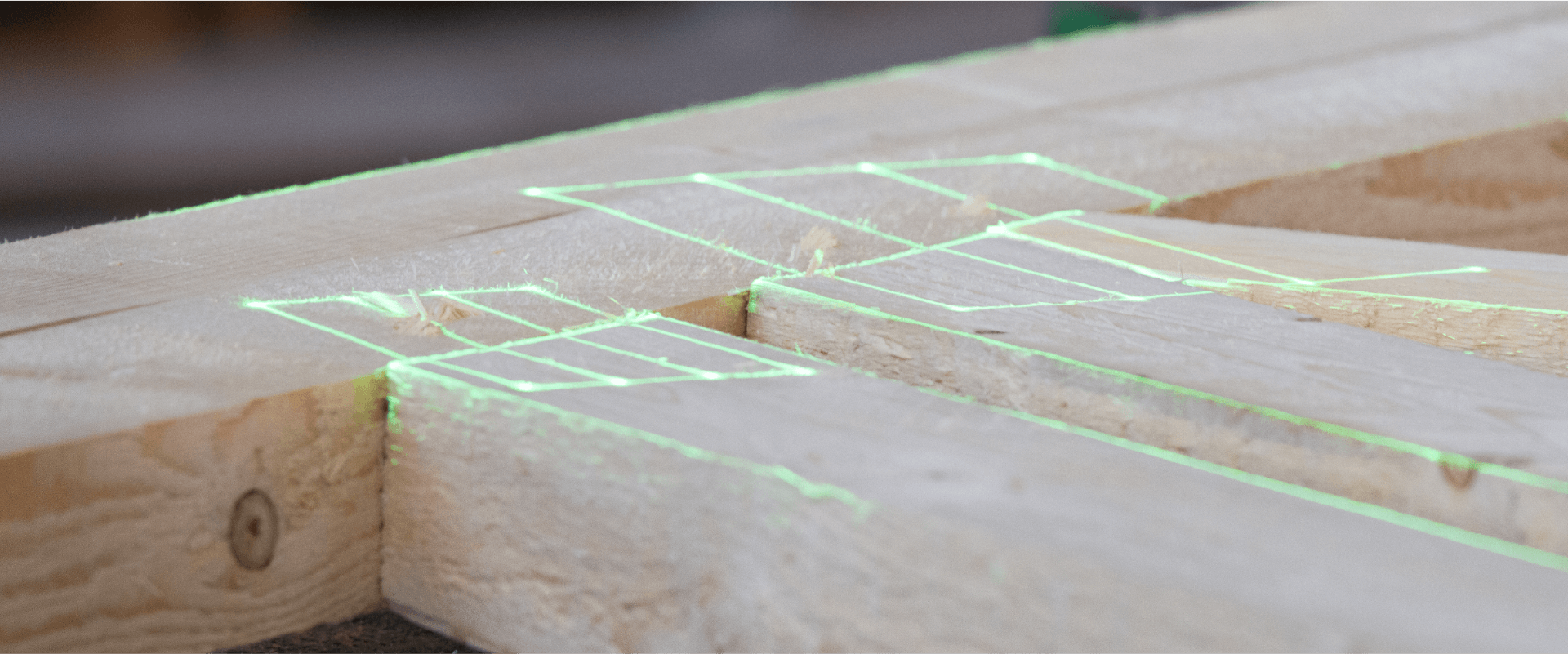

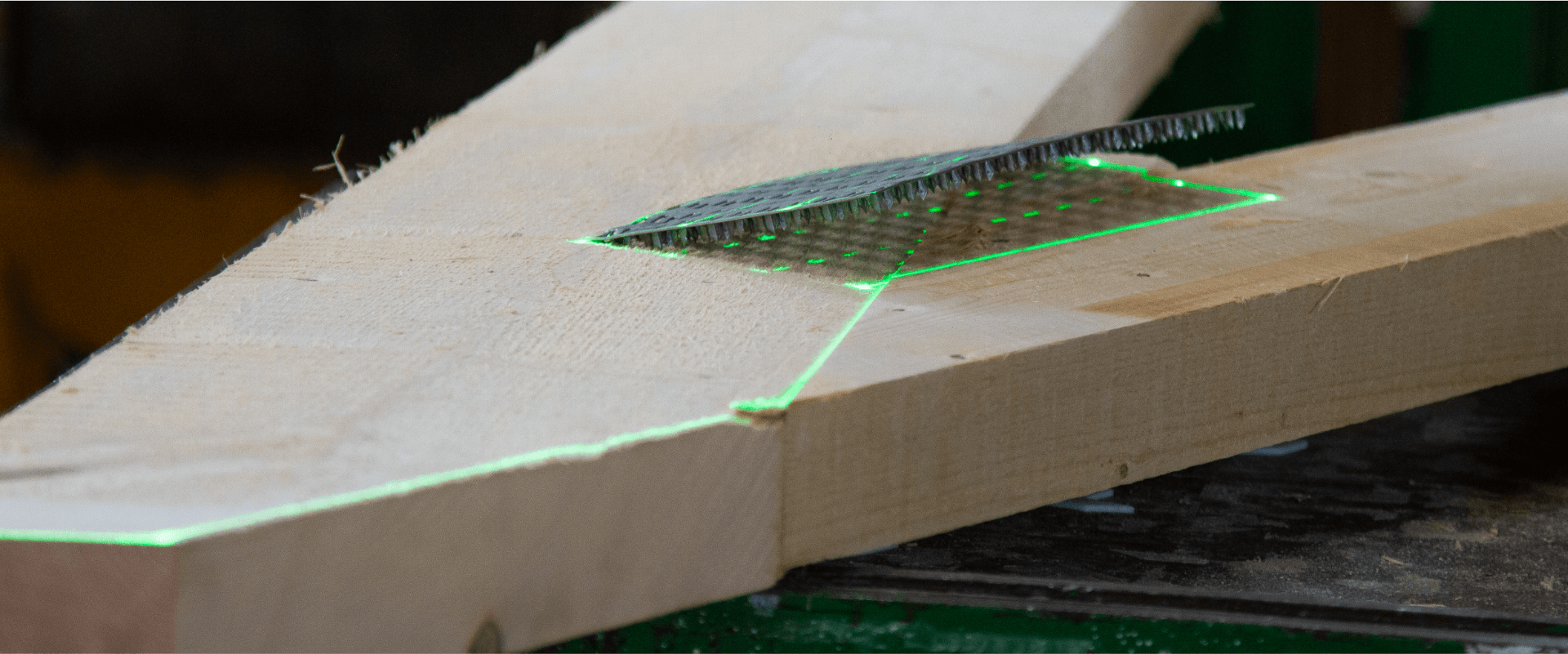

On demand, the outlines of the trusses taken from your CAD data are displayed accurately and according to scale by laser lines directly onto the working surface tables or C-press tables.

The term digital laser template is also used in this context, which accurately shows the correct arrangement, position and alignment of the trusses as well as those of the nail plates. You can immediately start with the production of the trusses.

Faster Manufacturing Process

Time-consuming and error-prone manual re-measurement, alignment and marking are eliminated.

Higher Product Quality

Ensures that no nail plate is forgotten or applied incorrectly.

Faster Setup

By projecting the position of the truss being produced in advance, the position of the benches can be determined quickly and accurately without having to be laboriously corrected later. In addition, the position of the mounts / fixtures on the benches can also be projected.

Less Errors

Minimizes costly offcuts and rework.

Using Laser projectors can also assist

you in your business challenges!

Shorter Training Times

The visual guidance not only simplifies the work of your experienced workers, but also quickly guides young employees or unskilled temporary workers, during periods of substitution for example, to an error-minimized production process. Worker absences and bottlenecks will be easier to overcome, and offcuts and rework caused by unskilled personnel will be minimized. Start complete individual constructions immediately – e.g. studio trusses for residential buildings or special constructions. Just do the same with any new truss constructions in your product portfolio.

Quality assurance RAL-GZ 601 for trusses

By using laser projection to manufacture truss products, you will easily comply with the standards in sections I-2.3.3 Requirements for component properties of nail plate products, Arrangement of nail plates and I-3.3 Factory production control and self-monitoring.

Well prepared for the next generation

Between traditional craftsmanship and the increasing challenges of digitalization, the Z-LASER projector LP-HFD2 accompanies your manufacturing process into digital transformation.

Competitive advantage

Classic state-of-the-art construction is your way: Secure your position on the market as well as that of your products by

introducing digital laser templates for your production in a timely manner.

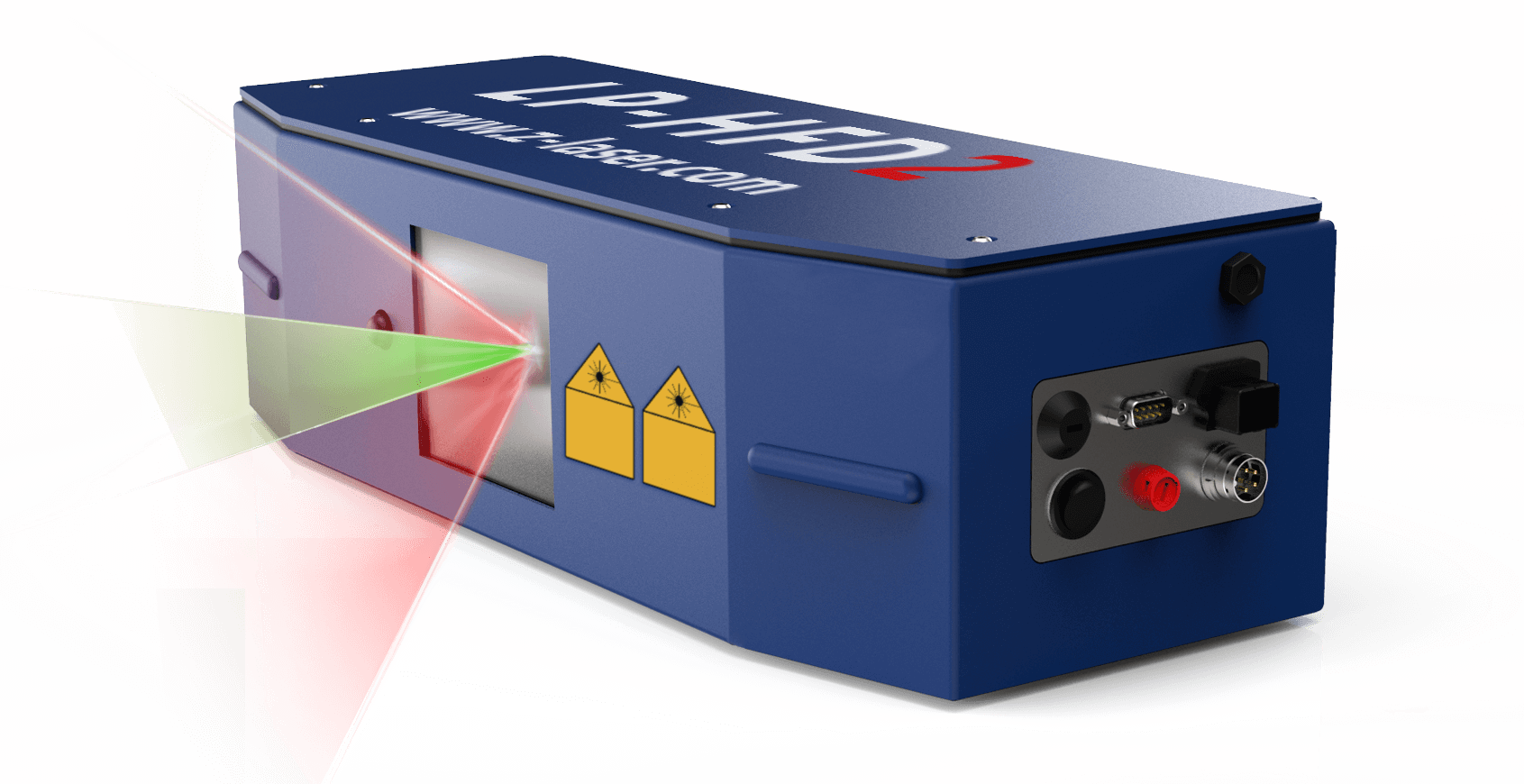

Our product for your application – LP-HFD2

Z-LASER has been offering industrial lasers as optical guidance systems since 1985 and now has 20 years of experience in the truss market with dozens of satisfied customers. Due to its robustness, the HFD2 model has proven itself.

Green Wavelength

The green laser line is better perceived by the human eye than red or yellow. The output power of 7mW enables laser class 2M classification.

Laser class 2M

Different from devices with a higher laser class, laser class 2M does not require a laser safety expert. You avoid the certification of such a person and the associated costs. Of course, we also offer devices with higher output power (14mW).

Casing IP 65

IP65 indicates dust-tightness and protection against heavy seas. Therefore, the housing is ideally suited for the dusty production environment of the woodworking industry.

Accuracy 0.25mm/m

Take efficient action to ensure the right placement for the nail plates onto the pre-fabricated load-bearing trusses with an overall shift to all directions of less than 5 mm.

High-power laser with thermal management

Easy control of laser projectors

Great value has been set on controlling the laser projectors in an easy manner and by direct communication between laser projector and environment.

Remote Control

Any command that can be executed by the software, can be assigned to the remote control.

Toggle single layers – only nail plates, or only trusses, for example – or display all at once.

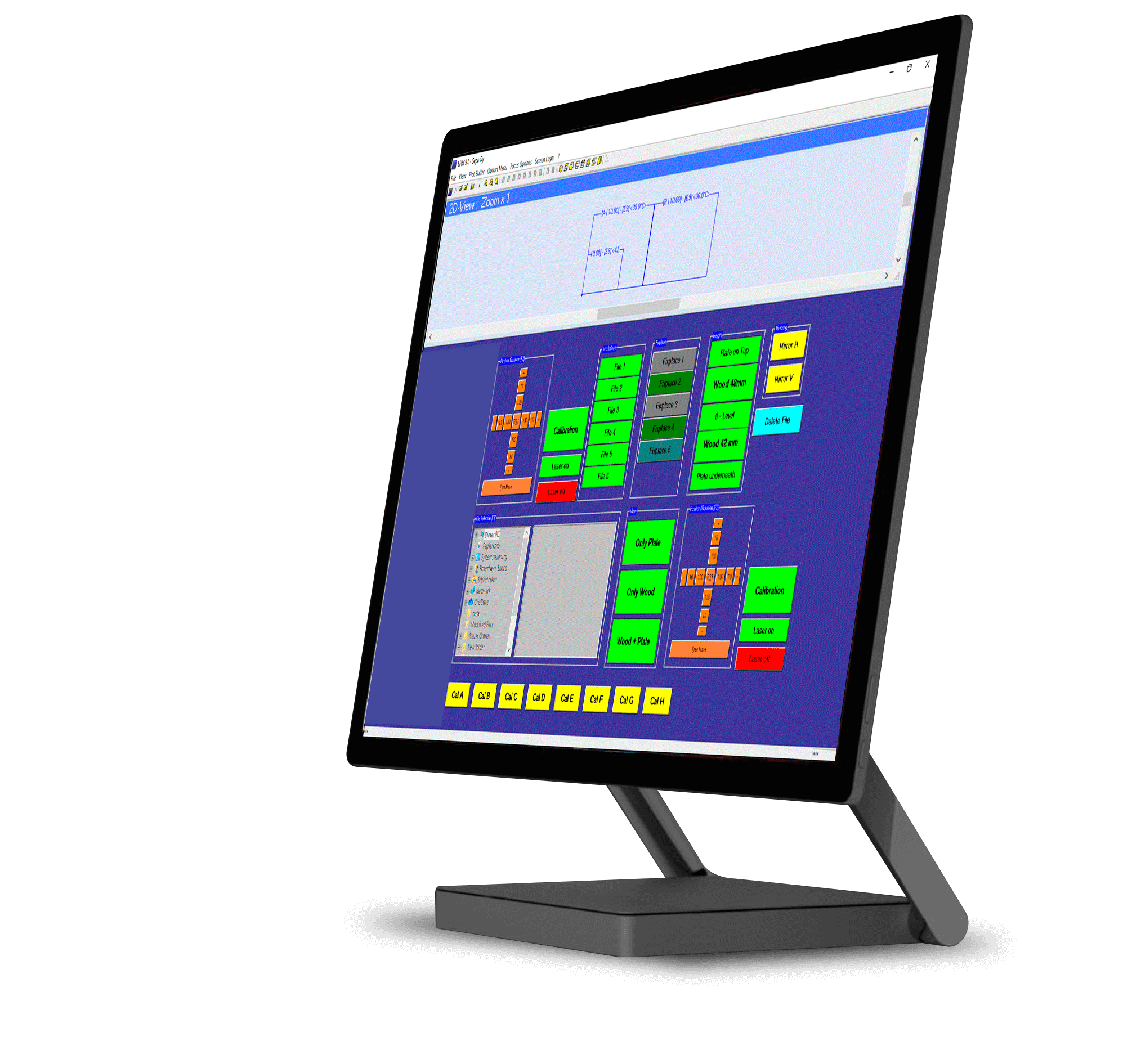

Software LPM

Use the intuitive software to select the file to be projected (usually DXF). It will be transferred to the projector for display. The intuitive user interface can also be customized to meet your unique needs. This makes handling and teaching much easier. User administration via password protection prevents unauthorized access.

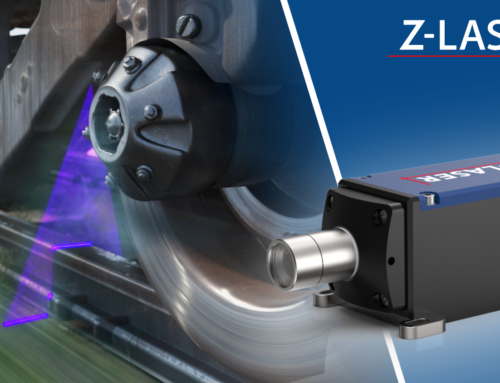

Laser projection is suitable for both C-presses as well as flat tables

Laser projectors are usually mounted above the working area beneath the roof top by using a special universal mounting – but a sidewall mounting is also possible. The maximum field of projection is depending on mounting height and projection angle.

Multi-projection systems

Up to 16 projectors can be connected and divide projection data among them.

Fast calibration

The daily calibration process done by just pushing a button only takes a few minutes – to project your CAD data true to scale and accurate every day.

Selection of single fields

Define fixed projection parts and select single fields to project within.

Download our application brochure