In industrial image processing, machine vision plays a key role in tasks such as quality control, process monitoring or product inspection. At the core of these applications is an optical measurement system, which captures geometries, surfaces, or positions with high precision and without physical contact. Measurement accuracy depends largely on illumination. It defines image contrast and ensures that relevant features are reliably detected. In many industrial applications, structured laser illumination is used for this purpose – for example, through precise line projection in laser triangulation (also known as light sectioning).

What is a measurement system?

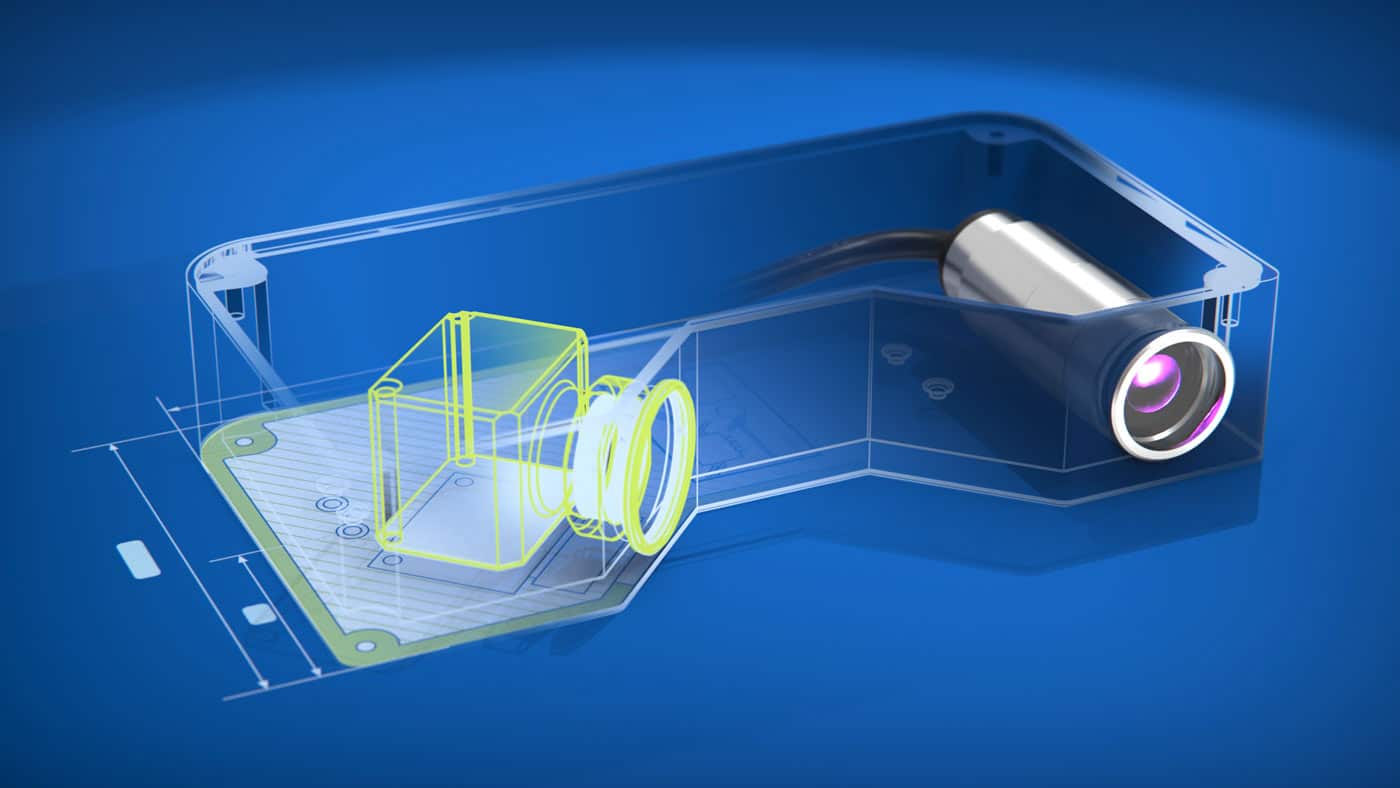

An optical measurement system combines hardware and software to quantitatively detect and evaluate the physical properties of an object. In industrial image processing, this typically means geometric features of components, such as length, width, angle or position. The core components of an optical measurement system are:

- Illumination unit: Generates a structured light pattern, such as a laser line, which is projected onto the object. It is essential for generating contrast and highlighting features relevant to the measurement task.

- Camera: Captures the illuminated object from a defined angle relative to the light source to obtain depth information, for example, via triangulation.

- Evaluation software: Processes the camera image, extracts the relevant measurement data, and compares it to reference values or tolerance limits (target values).

Modern systems also include intelligent measurement systems, which use additional references or known geometries in the measurement field to self-calibrate. These systems can also automatically adapt to changing environmental conditions, dynamically adjusting parameters such as exposure time or laser power. The measurement results are transmitted directly to higher-level control systems, allowing real-time process control and early detection of quality deviations.

The laser’s function: Structured illumination for precise 3D measurement

Laser triangulation, or light sectioning, is an established standard for the precise optical measurement of three-dimensional object contours. A sharply focused laser line is projected onto the object, while a camera captures the line from a defined offset angle. Based on the deformation of the line, the software calculates the 3D contour of the object point by point with high resolution and repeatability.

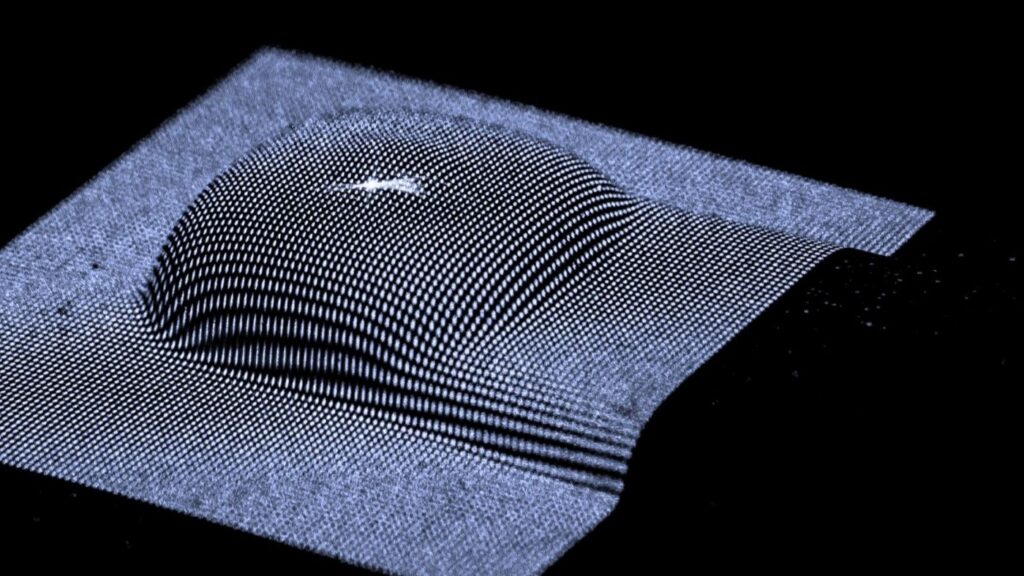

The quality of this method depends directly on the laser line’s properties. To ensure accurate measurement results, the line must be

- perfectly straight, as any curvature can lead to errors in the reconstructed geometry,

- sharply focused, to ensure that the software can detect edges clearly,

- evenly illuminated, so the line can be reliably recognised across its entire length, even at high processing speeds.

Only when these conditions are met can the triangulation process deliver stable and precise 3D measurement data.

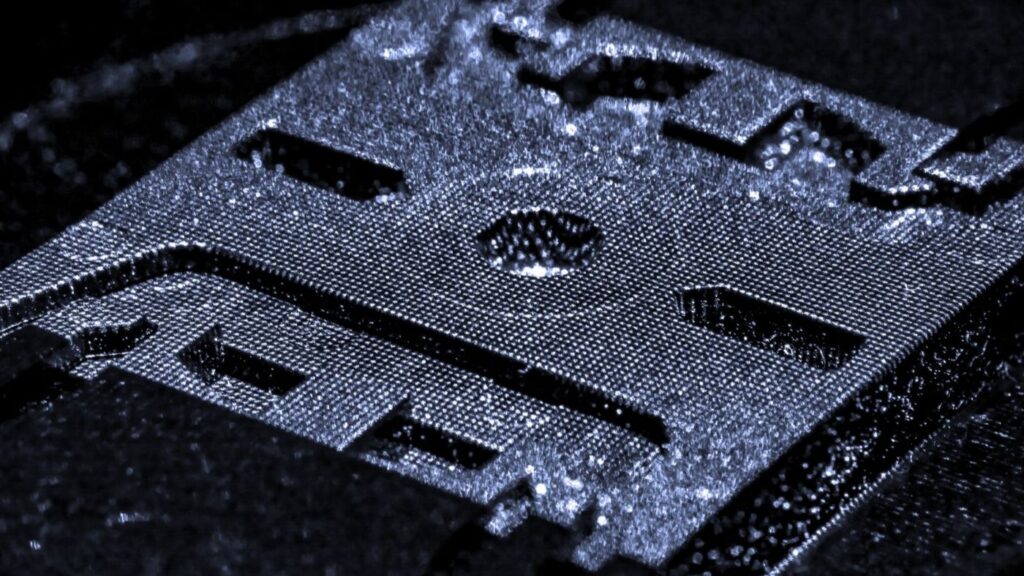

Z-LASER: Precision through automated optics alignment

Lasers used in machine vision systems must meet the highest standards for precision and repeatability. Z-LASER ensures this through fully automated production processes and robot-guided optics alignment. This guarantees that the projected laser line is straight, sharply focused, and evenly illuminated across its entire length. Thanks to their precision and flexible configuration options – including wavelength, output power, form factor and interface – Z-LASER lasers are the ideal light source for any demanding measurement system. They capture spatial contours with high accuracy and repeatability, even at high processing speeds.

Conclusion: Maximum measurement accuracy with structured laser illumination

In optical measurement systems, the accuracy and usability of measurement data depend largely on the quality of illumination. Proper lighting creates the image contrast required for sensors to detect structures clearly and for software to interpret them accurately. Z-LASER lasers offer high flexibility in terms of form factor, wavelength, interfaces, optics and output power. Automated optics alignment in the production process ensures laser lines with excellent straightness, precise focus, and uniform brightness. This makes them ideal for any demanding industrial image processing application, even under dynamic, high-speed production conditions.

Looking to enhance the performance of your measurement system? Get in touch with our experts to find the ideal laser for your application. Take your measurement system to the next level with Z-LASER!

Frequently asked questions

An industrial measurement system is a technical setup used to quantitatively capture product characteristics. In optical metrology, it typically consists of a camera, evaluation software and a precision light source – often a laser – to measure geometries, surfaces or positions without contact.

A laser produces a highly focused and precisely structured beam, typically in the form of a line. In light sectioning (laser triangulation), a camera can calculate the 3D contour of an object based on how this line is deformed. This would not be possible with diffuse illumination.

An intelligent measurement system goes beyond simple data acquisition. It communicates with higher-level control systems (e.g. in the context of Industry 4.0), adapts in real time to changing process conditions, identifies trends and calibrates itself automatically to new environments.

Optics alignment refers to the precise adjustment of optical components (such as lenses and mirrors) within a system. In a laser, precise alignment is essential to generate a straight, focused and uniformly bright laser line which is a essential for ensuring the accuracy of the measurement system.