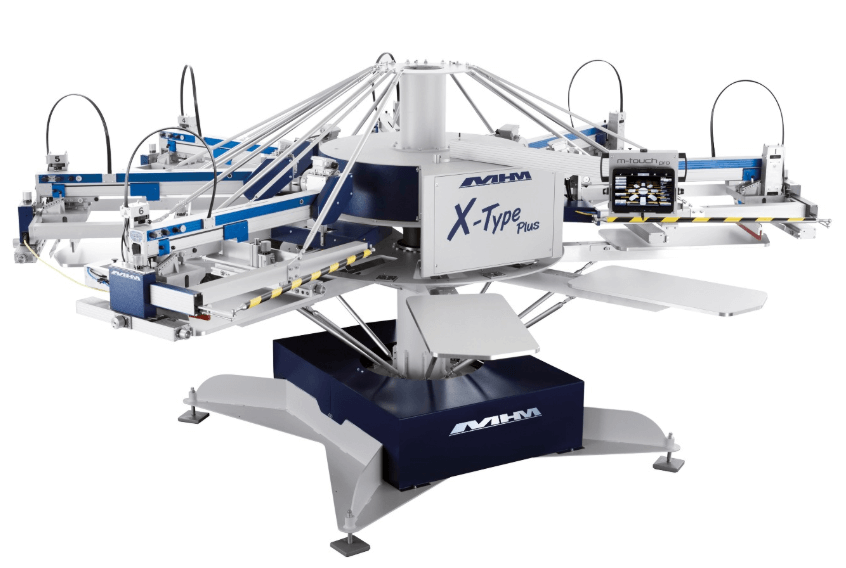

Textile printing is only one of many processes for finishing all kinds of textiles. This also includes embroideries or the application of so-called transfers. Textile printing is a screen printing process and is nowadays carried out in the industrial textile sector with so-called textile carousels, which are almost arbitrarily scalable – depending on the room size or desired output volume of printed T-shirts or comparable garments. The textile is pulled onto an empty pallet, successively approached by the screen carriers and dyed in different colors.

To ensure that all textiles in a batch are printed in the same way, it is necessary that they are always positioned in the same way on the pallet. This is where our positioning lasers come into play:

For example, one line laser can be used to display the center axis of the T-shirt; another serves as an orientation aid for the sleeve insertion points under the armpits. With this laser cross any textile can be aligned exactly and in a time-saving way! The lines can be created either with individual separately mounted line lasers or with a single laser with cross optics.

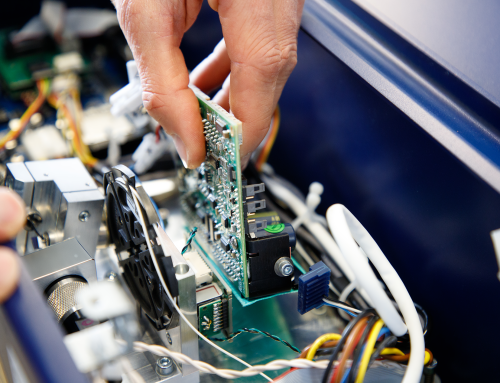

Challenge to the laser:

Highly visible red or green line, possibly even with brightness control for differently colored textiles.

Z-LASER recommendation:

Line or cross laser from the ZT series (red, dimmable), depending on the mounting height the model Z5T-645-lg90 or Z3T-635-lg90 (line) or the model Z5T-645-x30 or Z3T-635-x30 (cross with 30° opening angle in x- and y-direction – or equal the -x60 with 60° opening angle each).

As green lasers we offer you models from our new ZD-green series:

Model Z5D-520-lg90 (line) or Z5D-520-x52g (cross with 52° each in x and y direction). When choosing the color, please note that the lasers are less visible on backgrounds with the respective complementary colors, i.e. red on green or vice versa!

We will be happy to advise you on the selection of the appropriate product. Stefan Frei is looking forward to your contact.