The processing of sheet metal places high demands on precision and dimensional accuracy: when the material is cut or bent, it often depends on the tenth of a millimeter, a dimension that the human eye naturally cannot resolve without suitable measuring equipment.

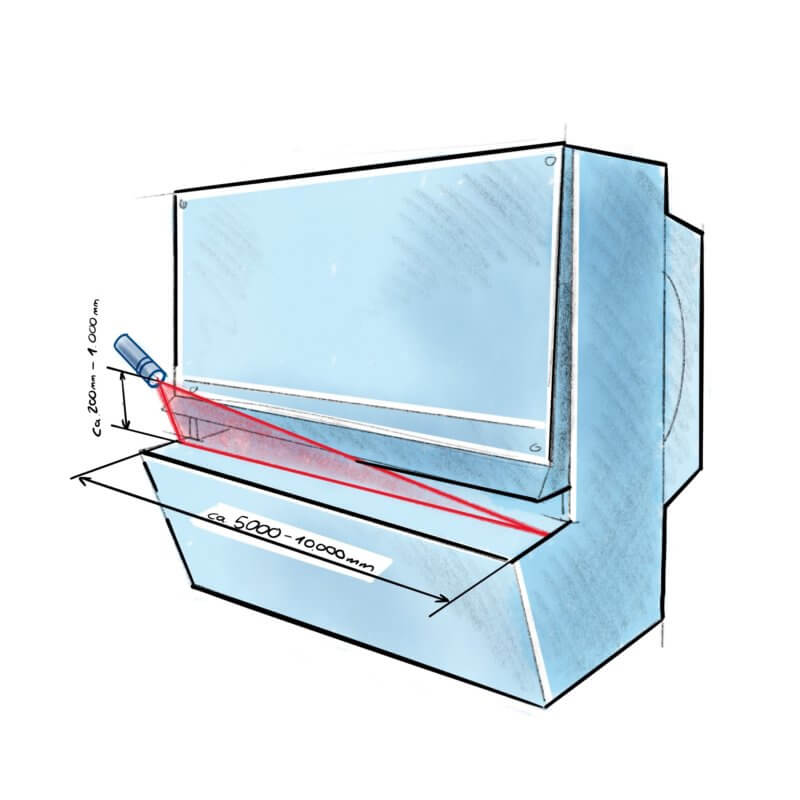

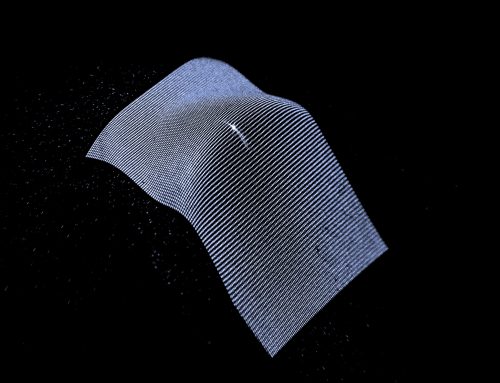

Line lasers used on sheet metal shears or press brakes to visualize the course of the cut or the bending edge must project long, homogeneously illuminated and yet as thin lines as possible from relatively low mounting heights if they are to be an aid to sheet metal workers in positioning their material. We pursue this concept with line lasers from the ZM18–lhi90a series.

The lasers are suitable for an installation height of 200 to max. 1,000mm, have a defined installation direction (see picture) and the lhi90a® optics distribute the light homogeneously over the entire required distance. A focusing optic, with which the customer can set the line as thin as possible, rounds off the product. Depending on the desired line length, we offer the product with different output powers as well as with red or green line.

In combination with our H6 or H8 precision holders, you gain the perfect positioning system for your sheet metal processing machine.

Do you have questions about this or similar applications? Our Sales Manager Stefan Frei will be happy to help you.