In modern manufacturing, precision and speed are crucial.

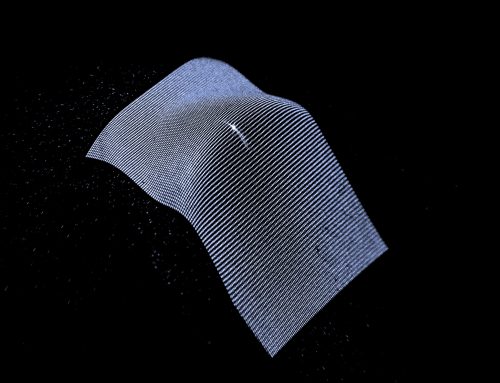

Laser triangulation offers an efficient solution for non-contact measurement of objects – ideal for industrial image processing.

Sie sehen gerade einen Platzhalterinhalt von Standard. Um auf den eigentlichen Inhalt zuzugreifen, klicken Sie auf den Button unten. Bitte beachten Sie, dass dabei Daten an Drittanbieter weitergegeben werden.

Weitere InformationenHow Laser Triangulation Works

A non-contact measurement principle based on geometry:

- A laser projects a line or point onto the surface of an object

- A camera captures the position of the laser spot from a defined angle

- The displacement is used to calculate precise height or depth data

Result: Highly accurate 3D profiles of surfaces and edges.

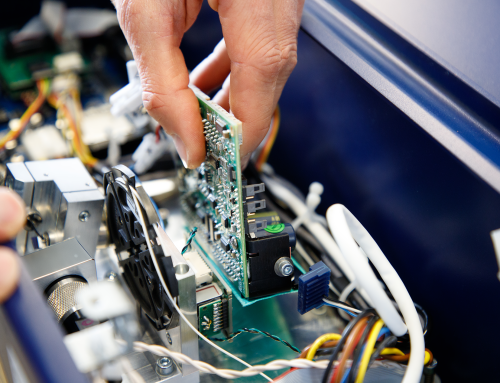

Applications in Industrial Image Processing

- Quality control in production lines

- Position detection of workpieces

- Form and dimensional inspection in serial manufacturing

- Robotics: precise position recognition for grippers

- Surface inspection in electronics manufacturing

Benefits of Laser Triangulation in Manufacturing

Why this method is in high demand:

- Non-contact & wear-free – ideal for delicate components

- High accuracy & repeatability – measurement precision in the micrometer range

- Fast & efficient – perfect for high-throughput inline processes

- Versatile – suitable for materials from metal and glass to organic surfaces

- Compact & robust – easy to integrate into existing systems

Conclusion: Efficient 3D Measurement with Laser Triangulation

Anyone relying on precise and fast measurement technologies in industrial image processing will benefit from the clear advantages of laser triangulation.

➡️ Interested in high-precision laser solutions?

Request a consultation now or go directly to our product overview.