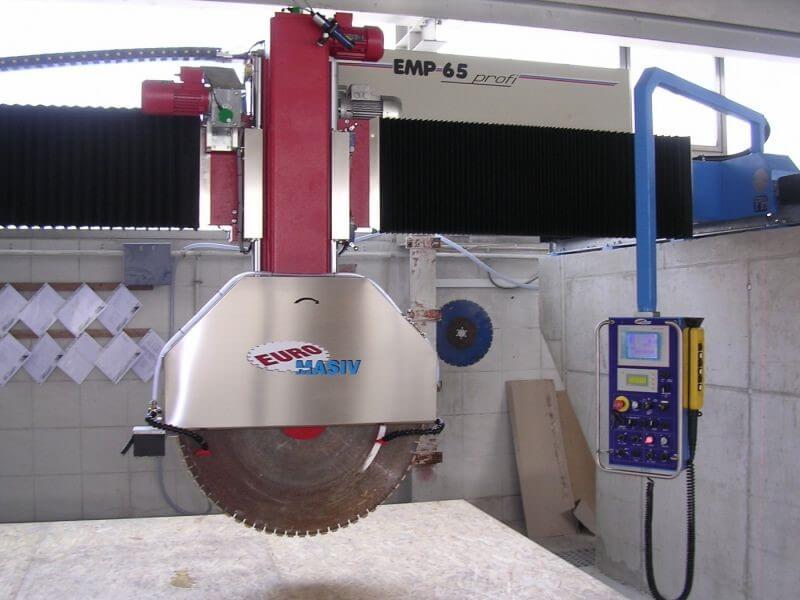

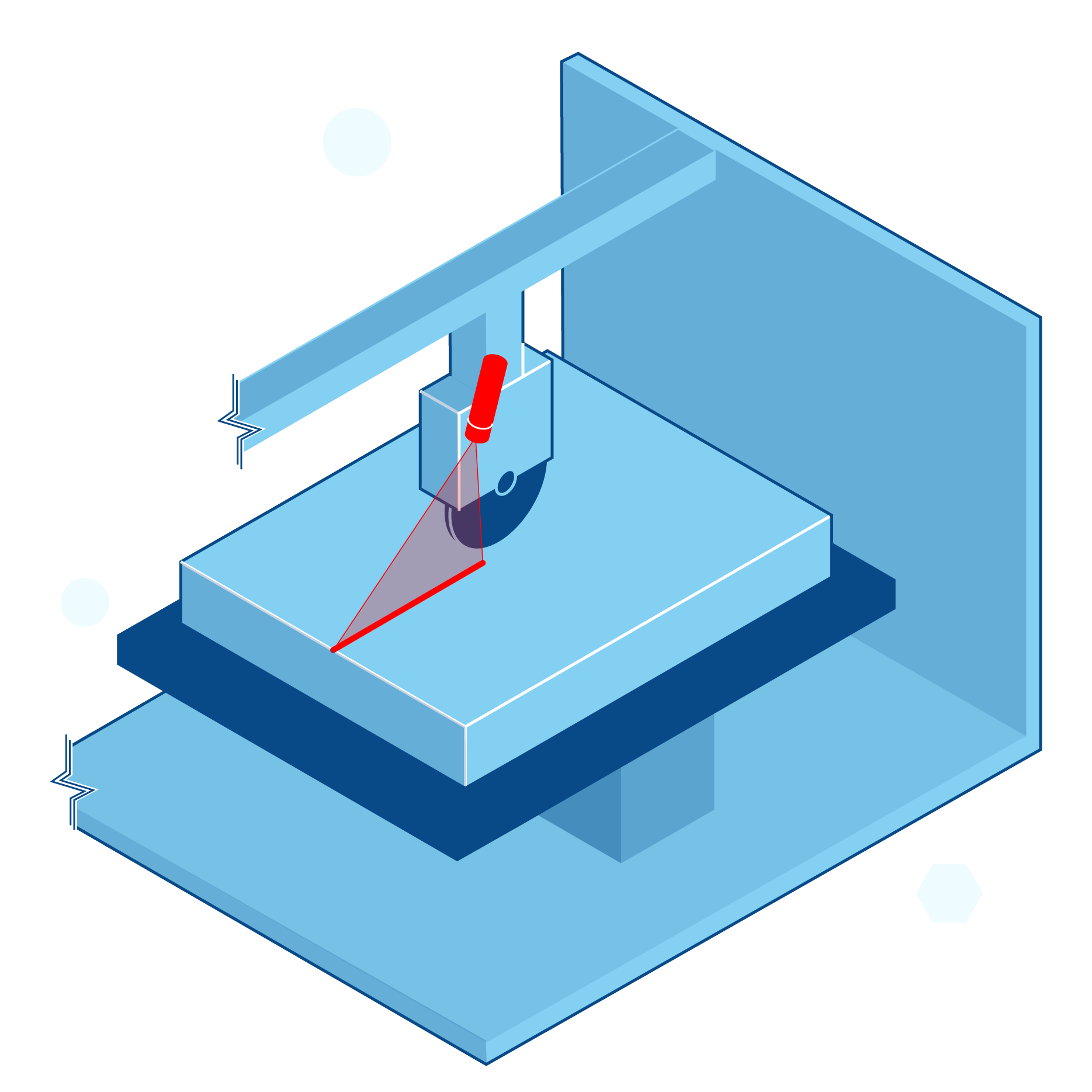

It is impossible to imagine a stonemasonry without the bridge saw: it is THE UNIVERSAL TOOL for cutting natural stone into a variety of formats or e.g. for processing kitchen worktops. The bridge saw has its name from the moveable cross beam, which stands like a bridge on two pillars or supporting walls. The so-called support, the actual processing unit, is mounted on the bridge. The most common tool is a diamond cutting disc, which is available with various diameters and degrees of hardness. The support can be moved in x and y direction as well as turned. On modern machine types (rotary head saws or 5-axis CNC machining centers) the disc can also be inclined to the vertical at any angle to achieve mitre cuts.

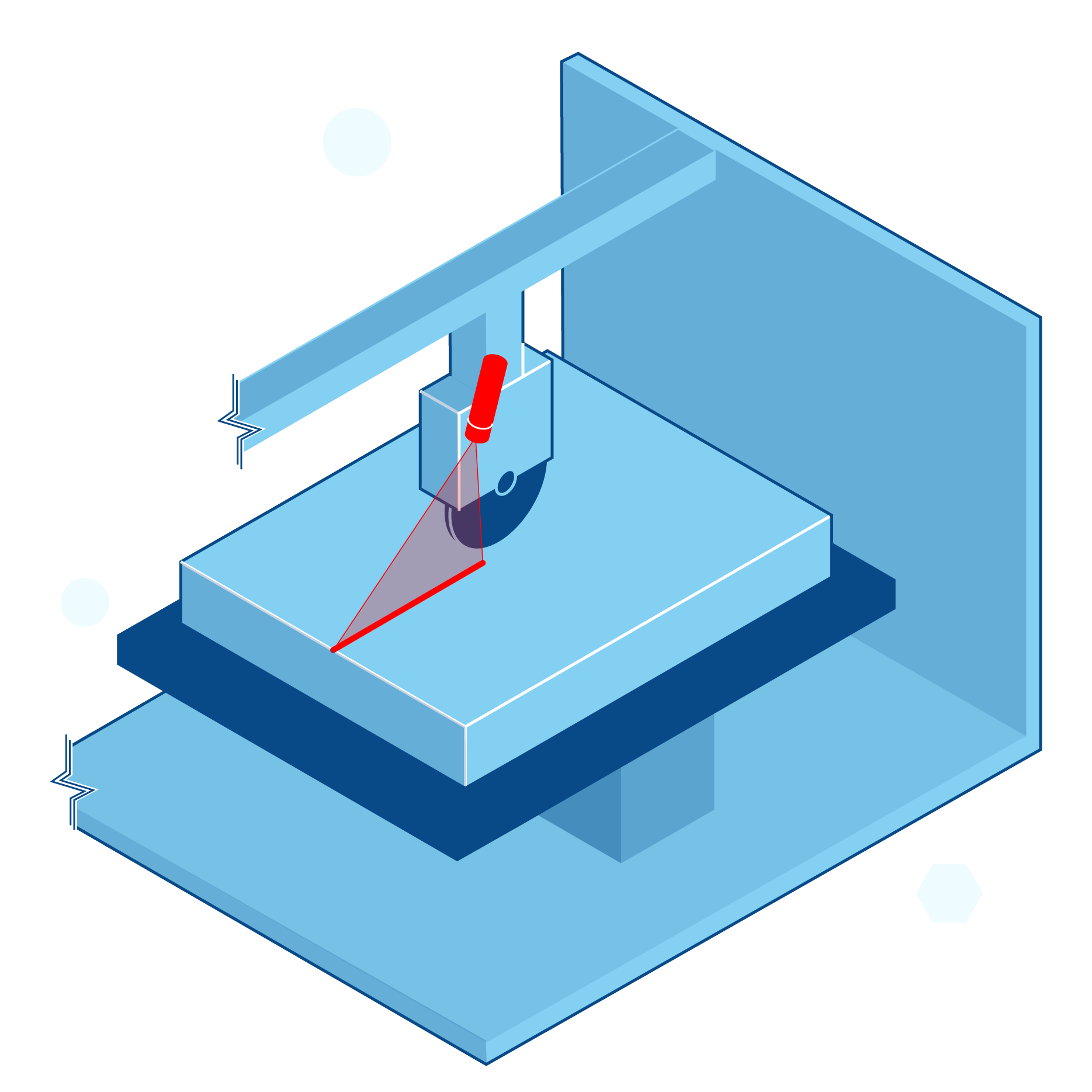

Natural stone is a valuable resource and therefore it’s necessary to avoid waste or rejects. This already starts with the positioning of the stone on the milling table: how do I get the best from of my slab? This is where the line laser comes into play: a red or green line indicates where the – pre-programmed – cut will afterwards cut the stone. Such a laser can basically be installed and used in two ways:

Mounting at the bridge:

From this position the line laser can cover the entire table.

From this position the line laser can cover the entire table.

Disadvantage: the line is projected only in x-direction and can only be moved in y-direction with the entire bridge. Most machine producers use a shaft with ø20mm as mounting option. On that shaft the laser can be mounted with a rotatable block mount of the H0 series and can be adjusted in the requires position. Important is the inclination of approx. 45° to the horizontal.

Mounting at the support:

As the laser is mounted significantly lower, the line is of course not as long, but can be swiveled with the support in all possible directions. A combination of both mounting options has proven to be a good solution. At the support housing the laser can be screwed to a bracket of the H2 series; if there is a mounting shaft with ø20mm the H0 is used as mentioned above.

The electrical connection is either via a separate plug-in power supply model WPS or directly to the machine control with 24VDC.

Challenge for the laser:

Line lasers in the natural stone sector must be robust, waterproof and also clearly visible on darker stone in a bright working environment. For years, red lasers with 15-40mW output power have been used, meanwhile the better visible green line lasers have become the industry standard.

Z-LASER recommendation:

Models from the ZM18 series: Red laser with 15-30mW(=milliwatt) output power or green laser with 20-40mW for mounting at the bridge (1). Red or green laser with 10-20mW for mounting at the support (2). We are more than happy to recommend you the best laser and accessories for your bridge saw.

Do you have questions about the use of our line lasers? Our Sales Manager Stefan Frei is looking forward to your contact.

From this position the line laser can cover the entire table.

From this position the line laser can cover the entire table.