Laser solutions for wind

turbine rotor blades

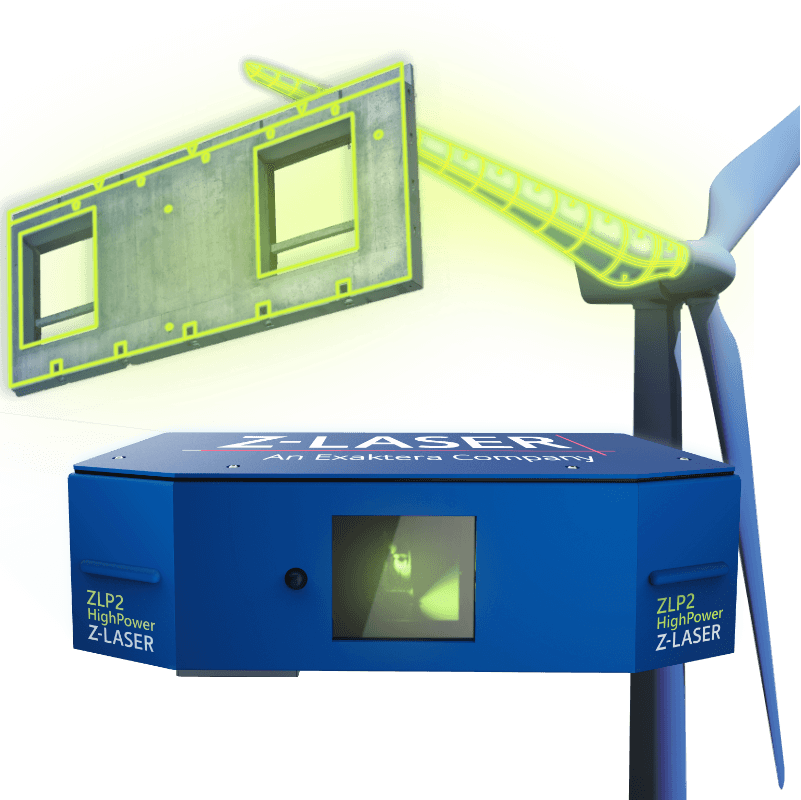

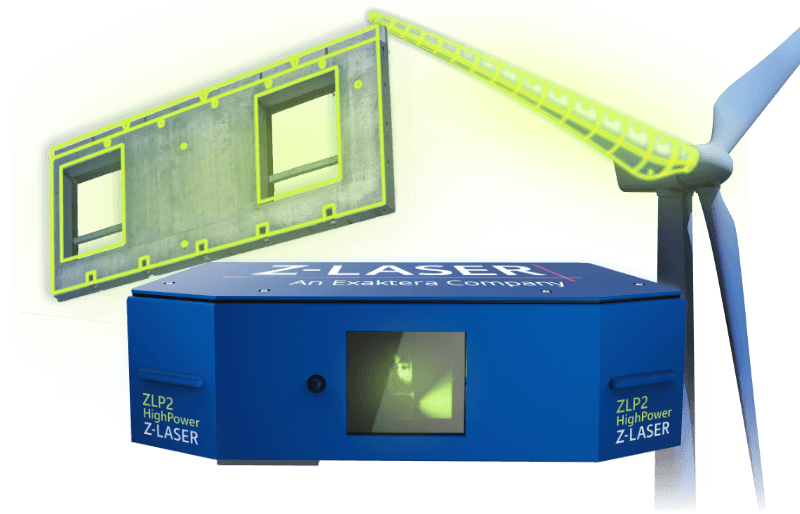

By using laser projectors such as the ZLP2-HighPower, wind turbine rotor blades can be produced faster and with higher quality.

turbine rotor blades

30% increased productivity, optimized quality and fewer errors:

with laser projectors from Z-LASER.

Energy transition with support from the Black Forest

Wind power is one of the fastest growing energy sources in the world and has the potential to drastically reduce dependence on fossil fuels. This makes it all the more crucial to manufacture wind turbines as efficiently and with as little use of resources as possible. Laser projectors from Z-LASER have proven their worth in this regard. By using them, it is possible to increase productivity in the manufacture of rotor blades by up to 30%, optimize quality and minimize human error.

Your challenge:

manufacture critical components more efficiently

A particularly complex manufacturing step in the production of a wind turbine is the production of the rotor blades: The laying, alignment and positioning of the glass fiber mats, prepregs and carbon fiber decals for this integral component is largely carried out manually in order to achieve the highest possible homogeneity of the rotor blades. This is crucial for energy efficiency and the service life of the turbine. Irregularities or shape defects in the rotor blades can impair the aerodynamics and thus lead to reduced performance.

Uneven loading due to varying wind conditions can also lead to vibration and increased wear of the rotor blades, resulting in higher maintenance costs and shortened wind turbine life.

It is therefore of great importance that the rotor blades of a wind turbine are manufactured with the highest precision and homogeneity to ensure optimum performance and longevity.

Our solution:

Laser projectors for homogeneous rotor blades

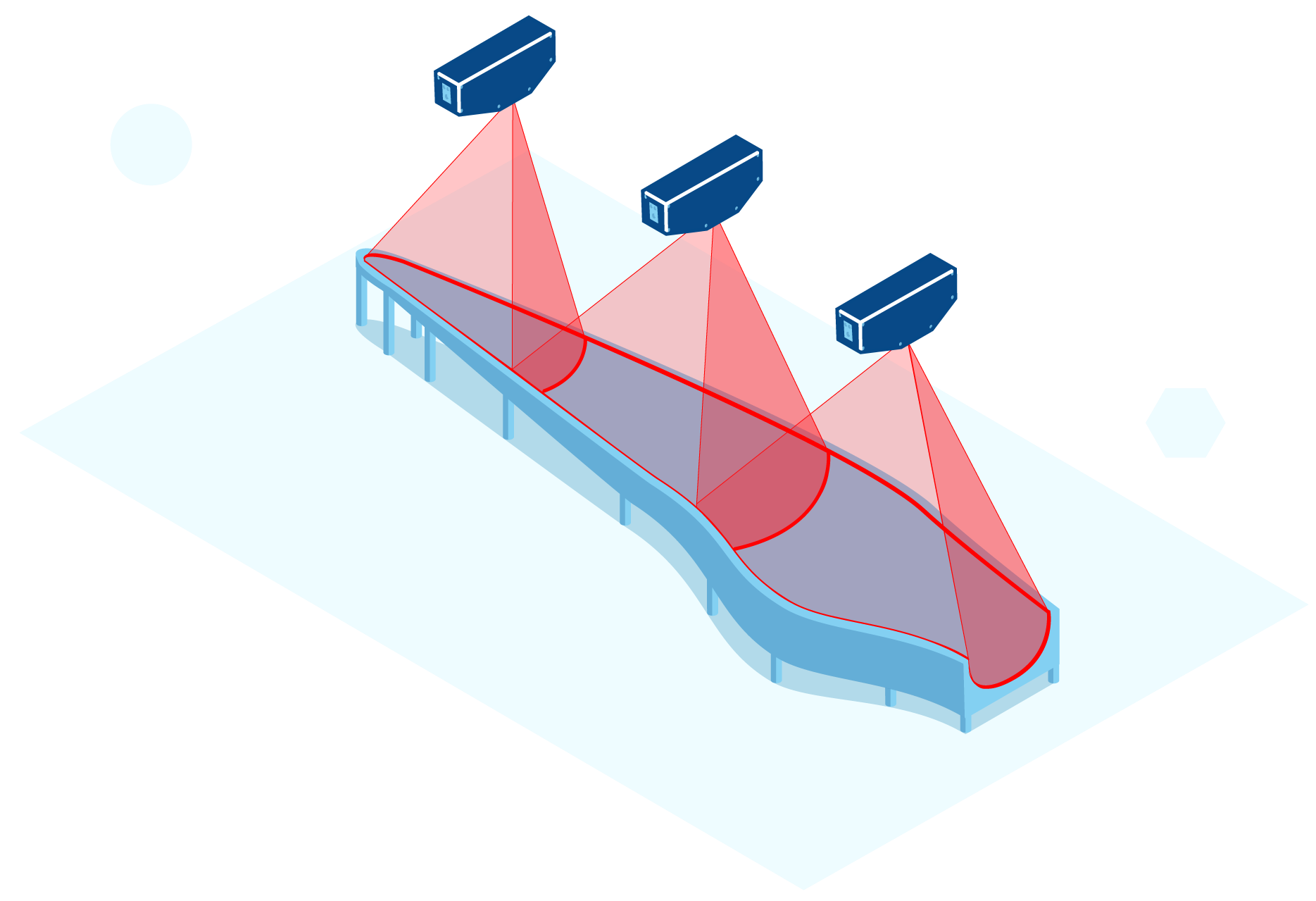

Our laser projectors have been specially optimized for complex positioning and alignment applications such as those encountered in the production of rotor blades. The projectors project the contours of fiber mats, decals, balsa cores or struts just as clearly and unambiguously as the placement points for vacuum cups.

At the same time, the laser projectors have interfaces for all common 3D CAD design programs to display contours even on curved surfaces.

In addition, individual letters, texts or numbers can also be projected to define specific projection patterns in more detail.

Your advantages with laser projectors from Z-LASER

Faster and more accurate positioning of fiber mats and decals.

Reduction of errors and manual rework.

Improved quality of rotor blades for higher performance and durability.

Integration with 3D CAD design programs for optimized contour display.

Increase throughput for more efficient production.

Sie sehen gerade einen Platzhalterinhalt von Standard. Um auf den eigentlichen Inhalt zuzugreifen, klicken Sie auf den Button unten. Bitte beachten Sie, dass dabei Daten an Drittanbieter weitergegeben werden.

Taking laser projection to a new level.

Now with 50% better visibility:

The new ZLP2-HighPower.

Groundbreakingly bright and impressively robust: Our new ZLP2-HighPower laser projector provides you with sustainable support for improving manufacturing processes and product quality.

Visibility

Precision

Efficiency

Longevity

Taking laser projection to a new level.

Taking laser projection to a new level.

Groundbreakingly bright and impressively robust: Our new ZLP2-HighPower laser projector provides you with sustainable support for improving manufacturing processes and product quality.

Visibility

Precision

Efficiency

Longevity

Success Story:

Nordex SE relies on Z-LASER

In this success story, read how laser projectors from Z-LASER help optimize rotor blade production at Nordex by positioning glass layers, patches and components to the exact millimeter.