(Bildquelle: Fotolia)

The wind power industry is experiencing exciting developments, bringing new challenges to the production of rotor blades. Here are three key trends shaping the sector today:

Larger Rotor Blades – Laser Projectors for More Power & Precision

To increase the efficiency of wind turbines, rotor blades are getting longer—often exceeding 100 meters. These giants capture more wind, boosting energy output. However, their production becomes more complex, as even the slightest inaccuracies can impact performance. This is where laser projectors come into play: they enable millimeter-precise alignment during manufacturing, ensuring the required level of accuracy.

Sustainable Materials – Green Lasers, Green Energy, Green Future

The wind power sector is increasingly focusing on eco-friendly materials to enhance sustainability. Innovative materials, such as recyclable resins and fiber composites, help reduce the environmental footprint. Laser technology supports this transition by enabling precise processing and minimizing material waste.

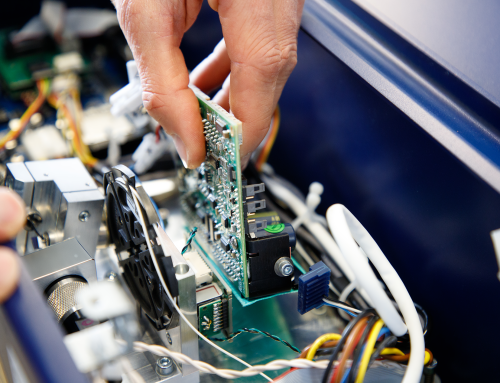

Laser Projectors Ensure Automation – Efficiency Meets Quality

Automation is a key trend in rotor blade manufacturing. The use of robots and digital control systems increases efficiency and ensures consistently high quality. Laser projectors play a crucial role by providing precise visual guides that speed up production, optimize processes, and prevent errors.

Conclusion: Advancing Wind Power with High-Tech Solutions

The latest trends in the wind power industry—larger rotor blades, sustainable materials, and automation—demand the highest precision in manufacturing. Laser technology, including laser projectors and positioning lasers, plays a vital role in overcoming these challenges and ensuring the future of efficient and sustainable wind energy production.