Laser projectors

Material and time savings thanks to laser projectors from Z-LASER

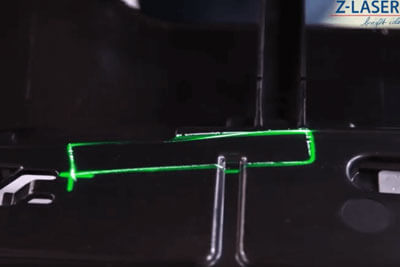

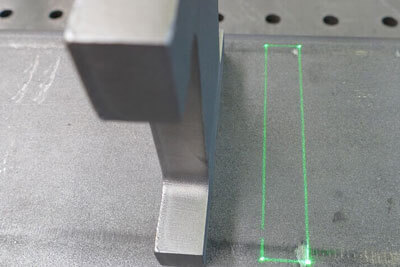

Industrial laser projectors serve as optical guidance systems. In many manufacturing processes, they allow working without templates by indicating directly on the workpiece how tools have to be positioned or material has to be mounted.

This can be the case, for example, in welding and assembly or in so-called light guide systems. In this way, laser projectors guide employees step-by-step through the assembly process.

The laser projectors from Z-LASER are particularly convincing due to their fast and stable projection with a high repetition rate, so that visual flickering is reduced or at best prevented. The Z-LASER laser projectors are optimized for 2D and 3D applications and offer a highly accurate projection in the sub-millimeter range. The optical angles (80° x 80°) allow the coverage of large working areas.

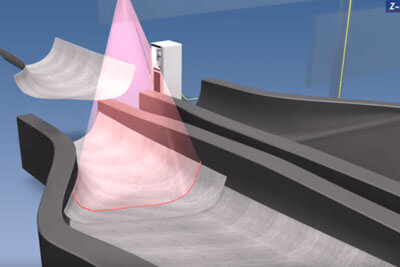

Z-LASER laser projectors can be combined into multi-projection systems. This enables large and very complex projections (e.g. shipbuilding, wind turbine blades for wind turbines, etc.)

Your advantages:

- Material and time savings through optimized workflow

- Higher accuracy and quality in production

- Immediate visual quality control

- Increase in production capacity

Control laser projectors quickly and easily – via GUI or SDK

Also for the control of the laser projectors, importance was attached to a simple and as direct as possible communication between laser projector and environment. With the Z-LASER software package ZLP Suite, the ZLP projectors can be easily operated and directly used via the GUI (Graphical User Interface). The integrated programming interface (API) supports a fast connection to existing customer applications.

Interesting and application examples for laser projectors

Laser projectors usually bring people and computers together. When used in worker guidance or in worker assistance systems, for example, the Z-LASER laser projector shows the worker in a flash where a screw has to be placed, where he has to remove suitable material or where a welding seam has to be placed. Thanks to optical work instructions, workers are guided through the production process in a targeted and effective manner; production processes can be optimized and made as economical as possible.

Examples of applications can be found here:

Z-LASER LP-HFD2

Hofmann GmbH in Blaufelden is one of the leading manufacturers in plant and apparatus engineering for the pharmaceutical...

DESC guidance

Our partner DE Group shows with the DESC worker guidance a complete system for worker guidance for most different application areas...

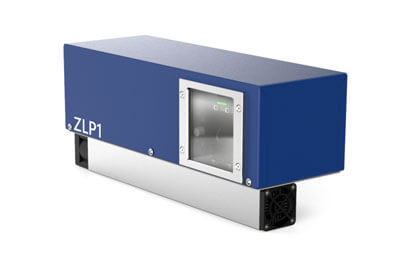

Laser projector ZLP1

The ZLP1 in use at Mayer GmbH, Laichingen or SKS Automotive in Mosbach. The Mayer...

Welding projects

Windmöller & Hölscher increases the reliability of correct execution with a laser projection system from Z-LASER...

Product Video ZLP1

Product video: The new laser projector ZLP1 by Z-Laser from Freiburg - presented by Manuel Gomez (Sales Manager)...

Product Video LP-HFD2

FKGroup, from Osio Sotto, Italy, is one of the leading machine manufacturers for the textile industry. Since...

Laser projector ZLP1

Z-LASER Optoelektronik GmbH is one of the leading manufacturers of laser sources in Germany...

Nordex & Z-LASER

Optimization of the production process of rotor blades with laser projection systems from Z-LASER. In 2017, one of...

Rotor blades

The manual laying process of glass fibre mats and prepregs in the manufacture of wind rotors can be carried out with the aid of laser projectors ...

Composite production

Weight reduction plays a very important role in vehicle construction. For this purpose one uses for more and more...

Aircraft production

In aircraft manufacturing, lasers are already successfully used for material alignment and tool positioning in assembly .

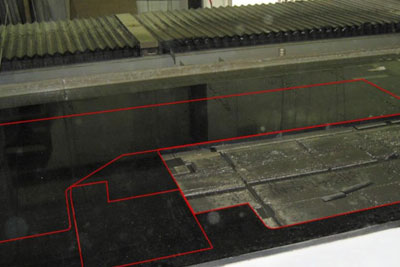

Leather Nesting

When cutting patterns made of leather with a cutter, unlike fabrics leather cannot be automatically nested, since leather as a natural material ...

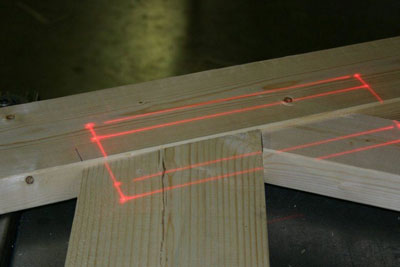

Nail truss construction

The laser projector creates a laser image from the nail binder construction files in original scale...

Your contact persons for laser projectors

Laser projectors ensure higher efficiency and quality in production

By means of selectable markings, such as geometric figures, letters, numbers or text, the employee is immediately shown where the next work step must take place (e.g. pick-by-light or put-to-light). Numerous information such as location, quantity, article number and name of the articles to be stored can also be specified and displayed by laser light. The exact position data is transmitted via the control software or a decentralised PLC control system. Since the optical signal guidance in tray warehouses – it is usually based on a geometric figure (tray geometry) – is free konfigurierbar, it can be easily modified and redesigned by the user. All laser projectors from Z-LASER were specially manufactured for industrial use and meet the highest demands at attractive prices.