Laser solutions for the tire industry

Z-LASER: The efficient way to more product and process safety, cost savings and flexible manufacturing.

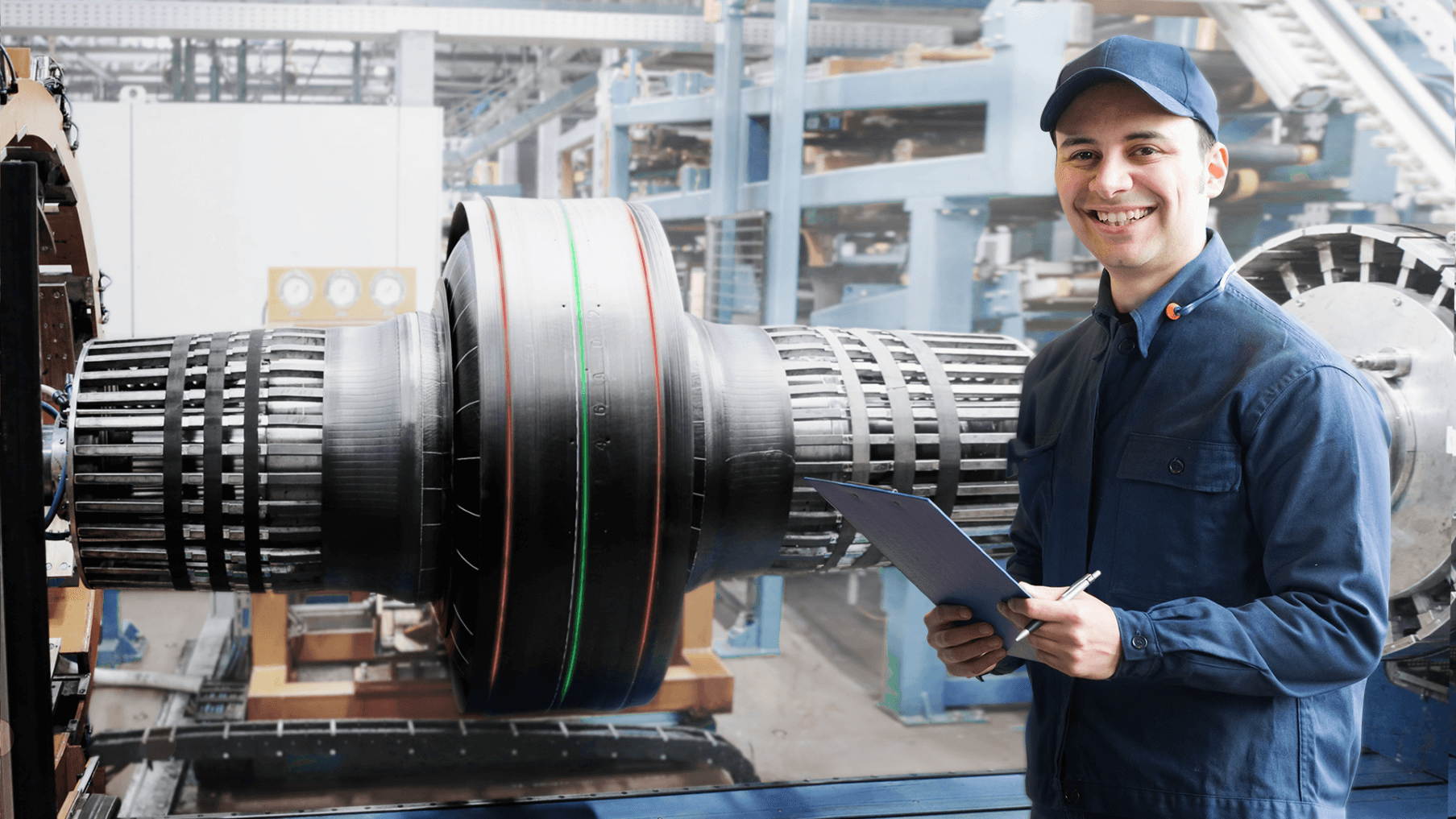

Here’s how lasers help putting power into motion

In Germany alone, almost 50 million tires are sold each year. Every single one of them must do its job safely and reliably – people’s health and lives depend on it. The production, inspection and preparation of car, truck and motorcycle tires are correspondingly demanding: Because even the smallest errors can have serious consequences.

With laser solutions from Z-LASER, you now have a highly efficient tool at hand to not only increase the safety of your products – you can also produce more efficiently, lower your costs and reduce environmental impact.

Your challenge:

Produce sustainably, safely and efficiently

Sustainability and environmental awareness

The tire industry is under pressure to develop more environmentally friendly and sustainable solutions. On the one hand, tires must be manufactured more efficiently, and on the other hand, there are demands to reduce energy consumption and CO2 emissions during production.

Competition and market dynamics

The tire industry is a highly competitive market with many global and regional players. Companies face the challenge of differentiating themselves through product innovation, quality, customer service and competitiveness. In addition, changing consumer trends, such as the increasing demand for online sales channels, are influencing market dynamics.

Technological change

The rapid pace of technological development is presenting tire manufacturers with new challenges. This includes, among other things, the development of special tires for autonomous vehicles and electric vehicles.

Our solution:

With lasers, your business runs smoothly

Sustainability and environmental awareness

Laser solutions from Z-LASER make it possible to produce tires significantly more efficiently, with less scrap and in higher quality. This means, among other things, that the required raw materials such as rubber and oil are used more sparingly.

Competition and market dynamics

The targeted use of laser-based inspection systems along the entire process chain ensures that you detect defects at an early stage, which guarantees the quality of the end products.

Technological change

Particularly in the case of tires for electric vehicles and autonomous driving, safety is decisive. Z-LASER ensures that you can safely and reliably detect any defects in the manufactured tires.

Your advantages with laser solutions from Z-LASER

Secure processes:

Highest precision in application ensures maximum safety.

Less cost:

Minimized human error and reduced scrap will lower your expenses.

Flexible manufacturing:

Respond to new requirements within production at short notice.

In action:

how laser solutions convince in application

Customized OEM solutions for your specific requirements

At Z-LASER we know that not every project can be covered with standardized solutions. Especially when the available installation space is limited, individual approaches are required.

Therefore, in addition to our standard available configurations of laser modules, we also offer OEM solutions for individual sizes. We look forward to finding the best possible solution for your project.