Laser solutions for the composites industry

With laser projectors from Z-LASER, you can increase efficiency and quality when processing composite materials – in every production step.

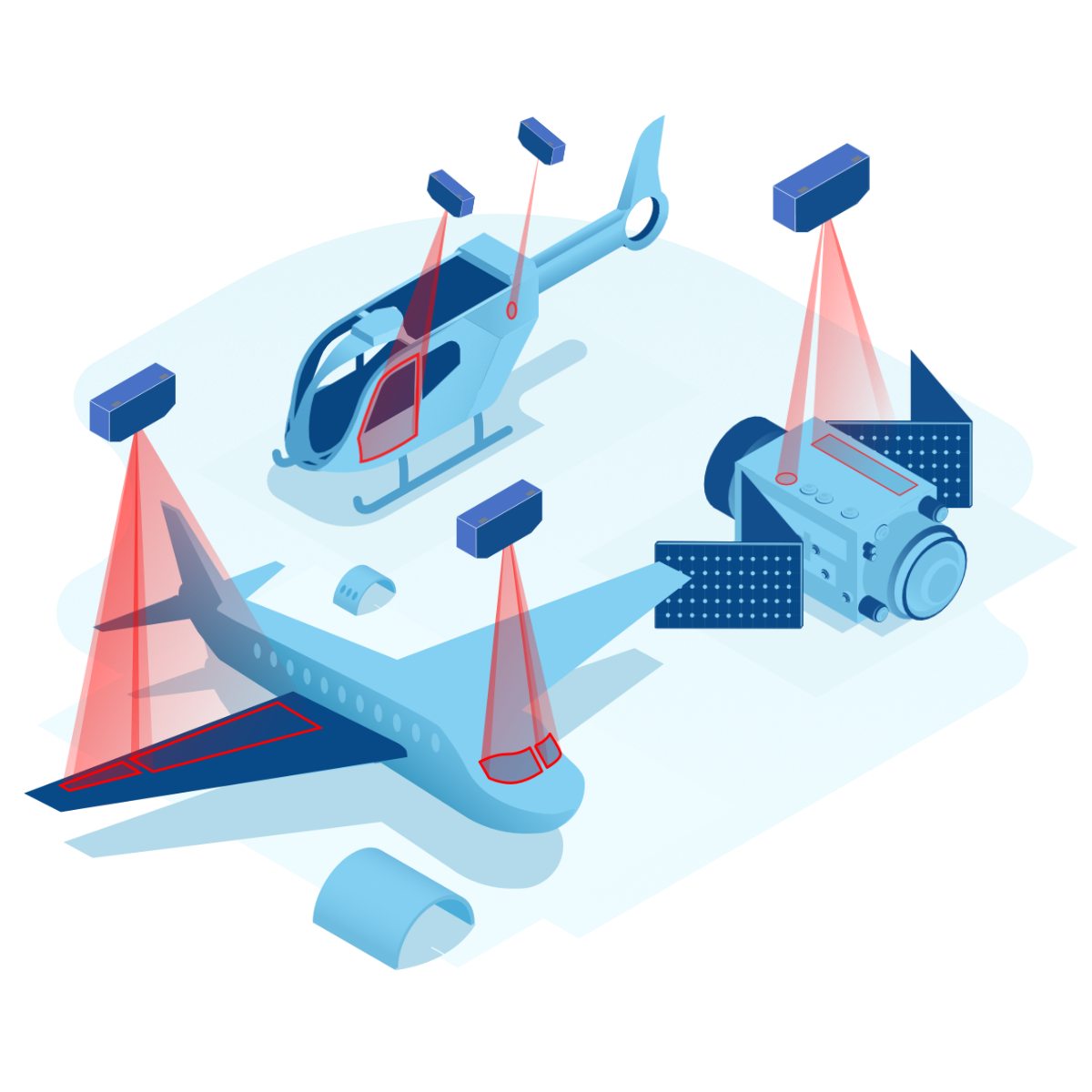

Aerospace

From the precise laying of fiberglass and carbon fiber mats to the production of complex aircraft and aerospace components: Laser projectors from Z-LASER are indispensable in the aerospace industry.

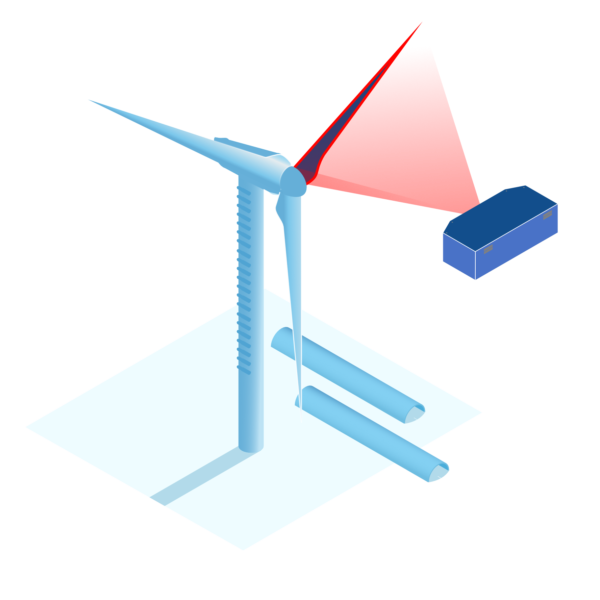

Rotor blades for wind turbines

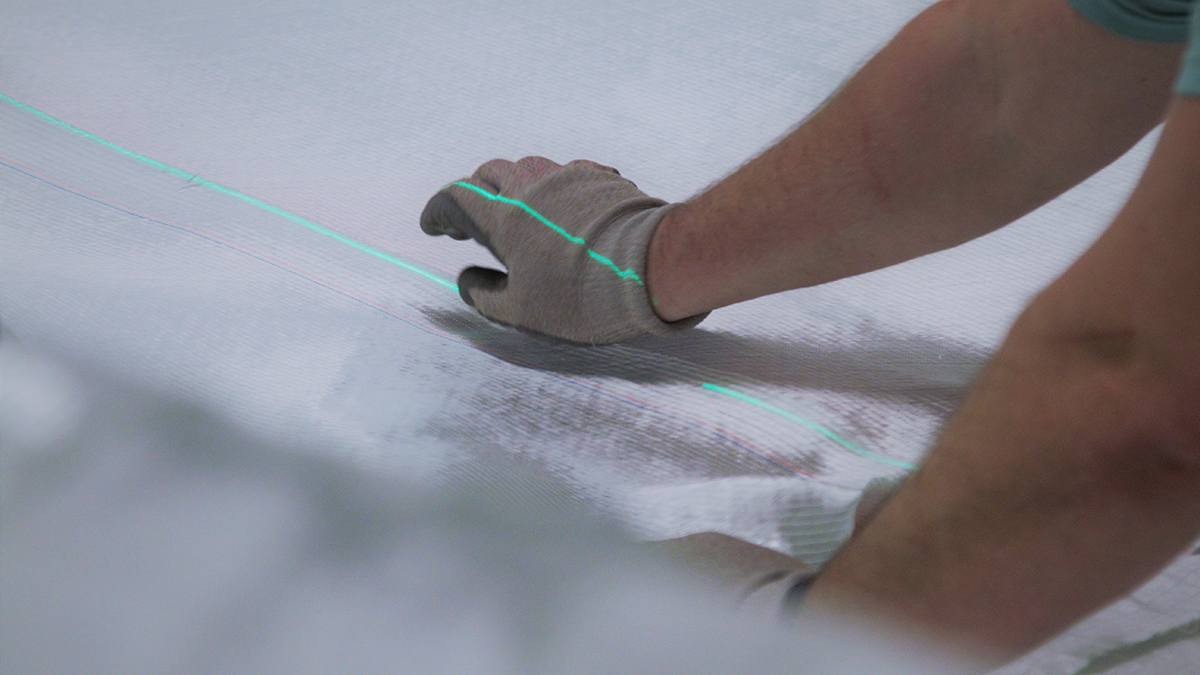

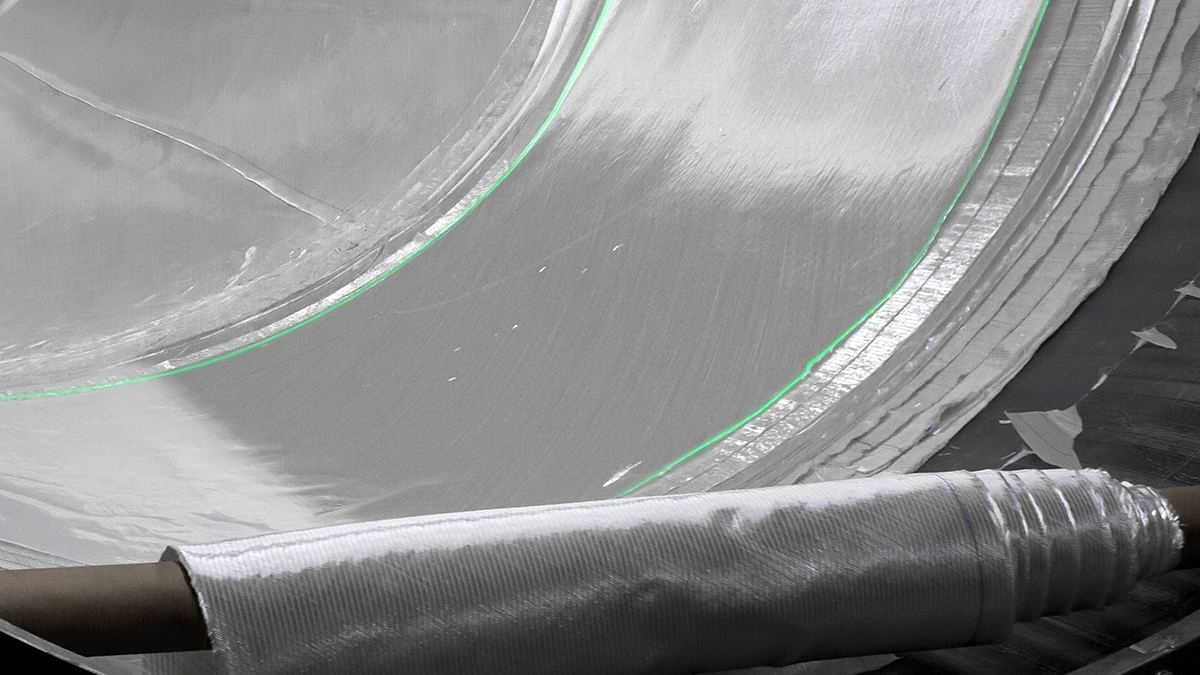

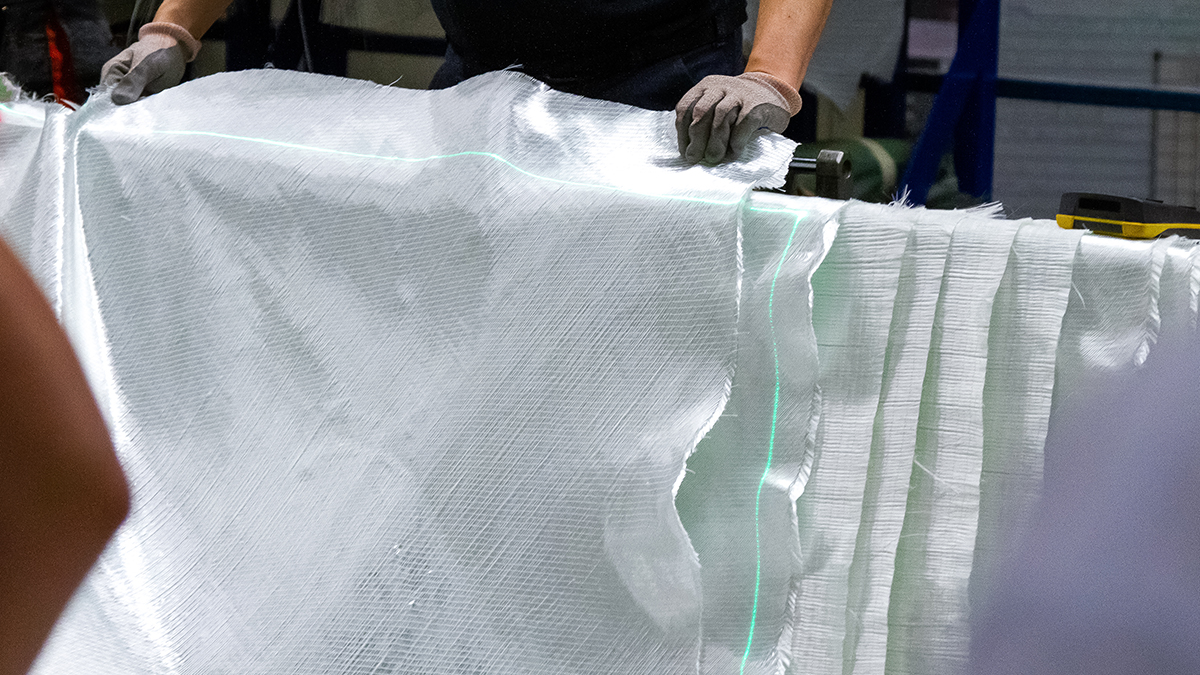

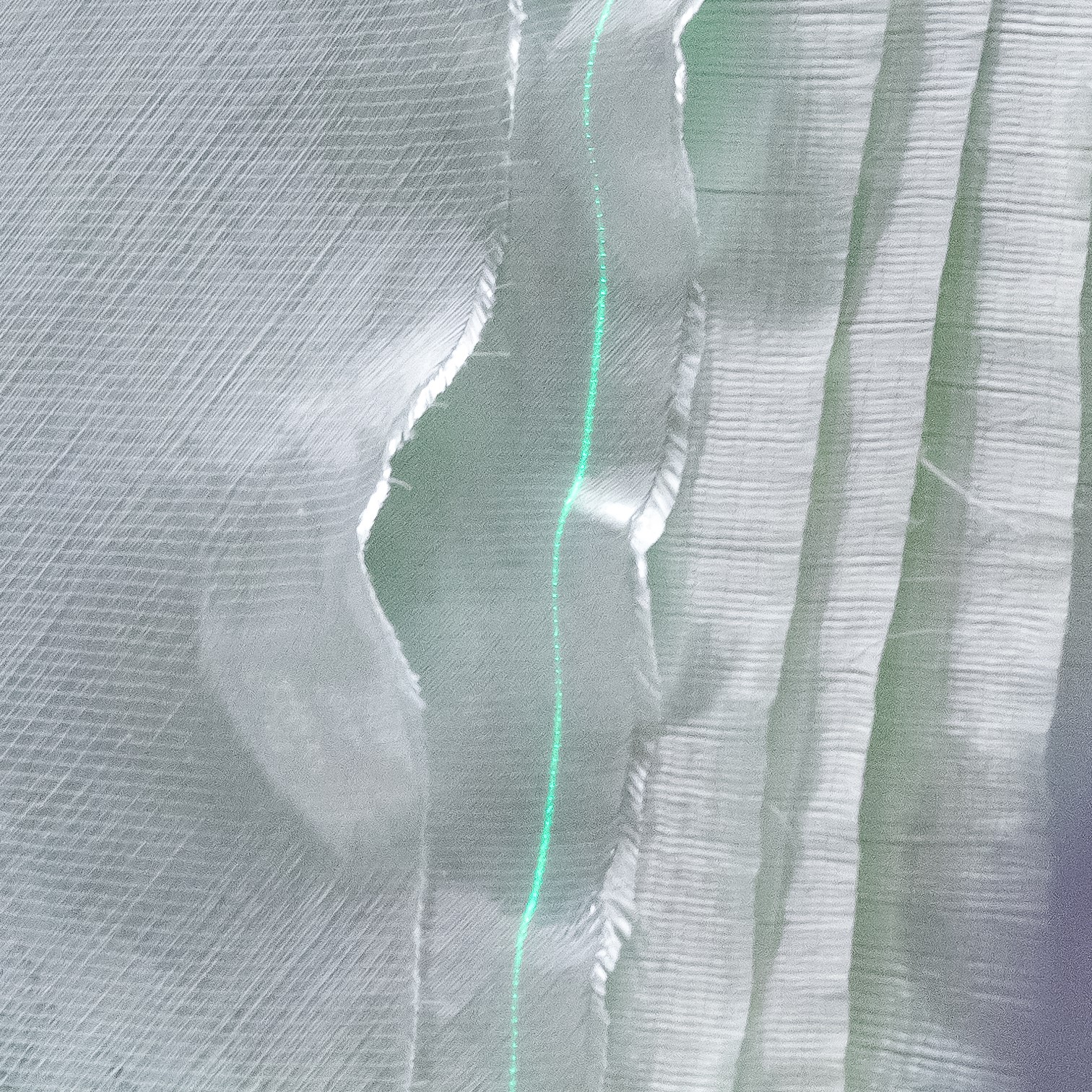

Laser projectors simplify and accelerate the positioning of fiberglass mats and prepregs in wind rotor production by precisely displaying the contours of each layer. They are compatible with common 3D CAD formats, increase productivity by up to 30%, improve blade quality, minimize errors and simplify the production process.

Z-LASER: The efficiency boost for composite production

Z-LASER optimizes production in the composites industry with highly developed laser projectors. Our solutions improve production speed and quality in areas such as boat and vehicle construction, aerospace and the manufacturing of wind turbine and helicopter rotor blades through precise 2D and 3D contour projections that enable fast and accurate positioning.

Compatible with all common 3D CAD programs, Z-LASER laser projectors facilitate the production of complex components and reduce errors, increasing efficiency and minimizing manual rework.

Your challenge:

to produce better, faster.

The composites industry faces numerous challenges, ranging from the precision of manufacturing processes to increasing efficiency and quality control.

Precise positioning and alignment

Accuracy in the placement of materials such as fiber mats or prepregs is critical to the structural integrity and performance of the end product. Imprecise positioning leads to weak points that can affect quality.

Efficiency in production

Time pressure and the need to speed up production cycles without compromising quality are a constant challenge. Manual processes are time-consuming and increase the potential for errors.

Quality control

Maintaining consistently high quality across different batches and production lines is difficult, especially with complex components and large production volumes.

Flexibility and adaptability

The ability to quickly adapt production systems to new designs or materials is crucial in a rapidly evolving market. Rigid production lines can hinder innovation.

Reduction of waste and rework

Material waste and the need to rework or replace parts due to defects are cost-intensive problems. Efficient use of raw materials and minimizing waste are key to cost efficiency.

Our solution:

laser innovations that make the difference

Laser solutions from Z-LASER offer innovative answers to these challenges by using state-of-the-art technology to optimize production processes and improve end product quality.

Precise positioning and alignment

Laser projectors make it possible to place and align materials more precisely. This improves the structural integrity of the components and reduces the risk of errors.

Efficiency in production

By eliminating manual measurements and markings, our laser projection systems speed up the production process considerably. Faster throughput times and increased productivity are the result.

Quality control

Z-LASER’s technology supports consistently high quality by ensuring accuracy in material placement. This minimizes errors and improves the overall quality of the end product.

Flexibility and adaptability

With interfaces for all common 3D CAD programs, our laser projectors enable a quick changeover to new designs or materials, which improves adaptability to market requirements and design changes.

Reduction of waste and rework

The precise projection of the materials to be placed optimizes material consumption and reduces the need for reworking due to errors. This leads to significant savings in material costs and improves the environmental balance.

5 reasons for laser projectors from Z-LASER

Increased precision and accuracy in positioning and processing.

Increased efficiency by automating processes.

Consistently high quality in production.

Flexibility through easy adaptation to different material thicknesses, types and complexities.

More efficient use of raw materials and reduced waste.

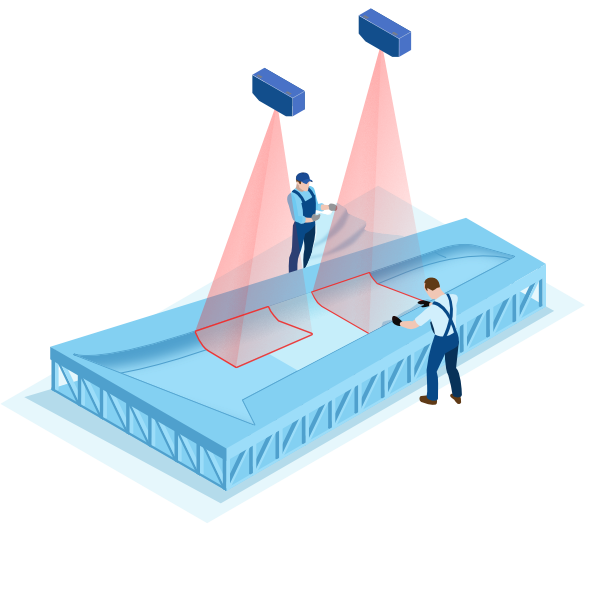

In Action:

How our laser projectors impress in the application

Customers from the wind power, aerospace, shipbuilding and architecture industries rely on our solutions because they minimize production times, reduce material waste and offer a high degree of adaptability to complex geometric design requirements and material properties.

Guide:

Everything you need to know about laser projectors for the composite industry

All applications and the right solutions – always to hand: in the compact guide “Laser solutions for the composite industry”. Download now free of charge and without obligation.