Sie sehen gerade einen Platzhalterinhalt von Standard. Um auf den eigentlichen Inhalt zuzugreifen, klicken Sie auf den Button unten. Bitte beachten Sie, dass dabei Daten an Drittanbieter weitergegeben werden.

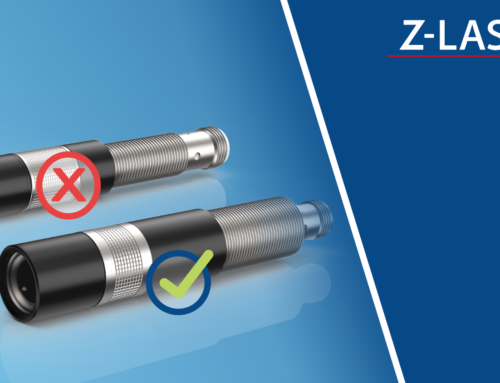

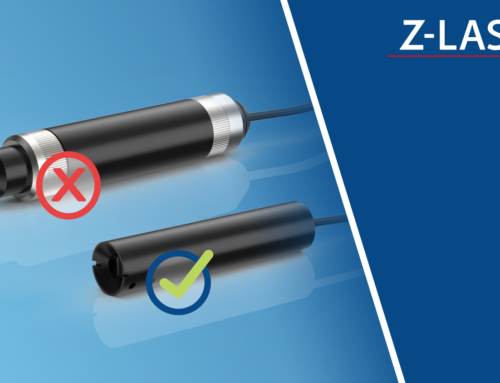

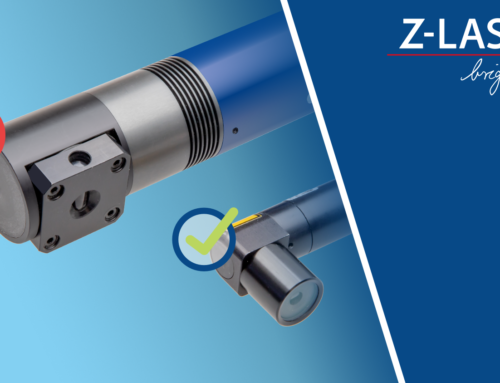

Manufacturers of laser triangulation sensors are increasingly moving towards integrating laser modules deeply into their systems, rather than seeing them as a “simple” component or accessory. This provides some significant benefits. The form factor of the laser system can often be considerably reduced and adapted to the existing constructional conditions. Likewise, the cost structure is optimized. However, it is important to maintain a high degree of flexibility to cover the large number of variants for all use cases of a product platform (wavelength, optics, output power).

Further considerations include questions in regards to field replacement without recalibrating the sensor, supporting all laser variants without impacting system integrity and maintaining laser safety. To further assist the OEM in reducing costs and form factor, driver electronics can be integrated directly into the PCB design using our licensed software. In order to reduce unscheduled downtime, there is additionally the option to read out operating parameters or a predicted potential end-of-life (EOL) warning.