The demand for Ø40mm lasers with L90 angle optics has decreased noticeably over the years. At the same time, the material costs have increased with the smaller quantities.

For these reasons we discontinue the variant L90 from the ZR, ZPT-F and ZRG-F in short term.

But don’t worry! There are good alternatives from our ZM18 Laser family:

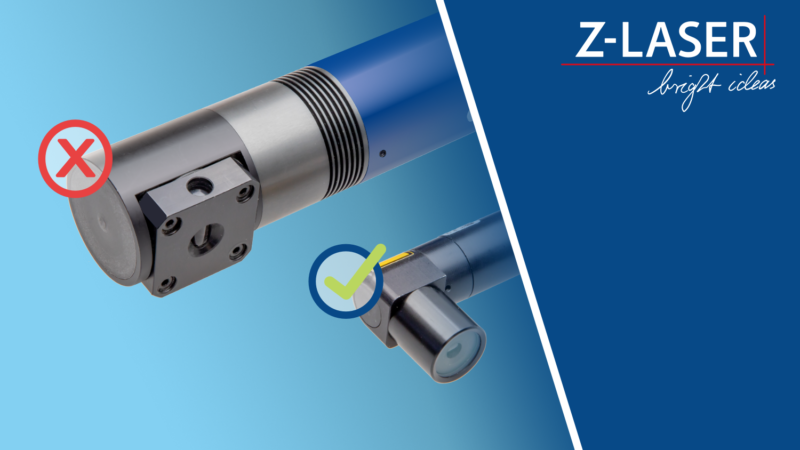

– ZM18 with deflection optics L90 as ZM18-L90

– ZM18-lhi90a („deep spotlight“) for long lines with low installation heights

But what’s the meaning of deflection optics? If you are interested, you should continue reading from here:

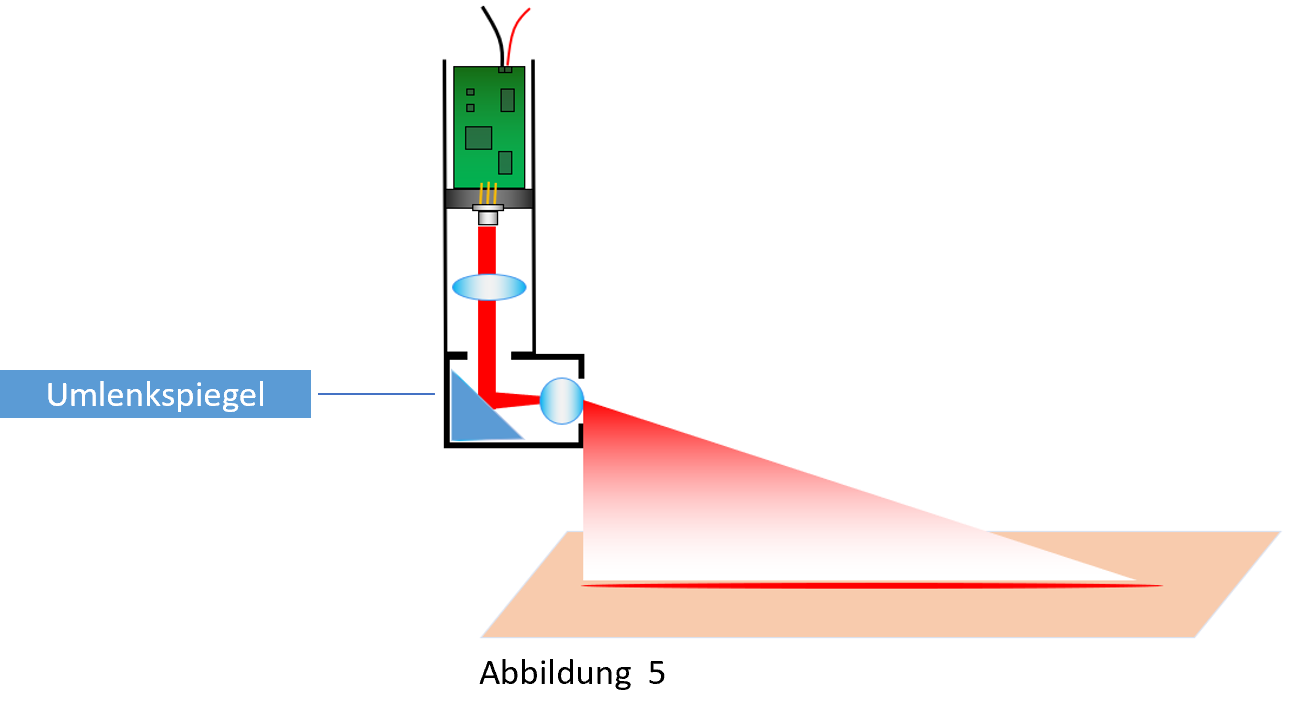

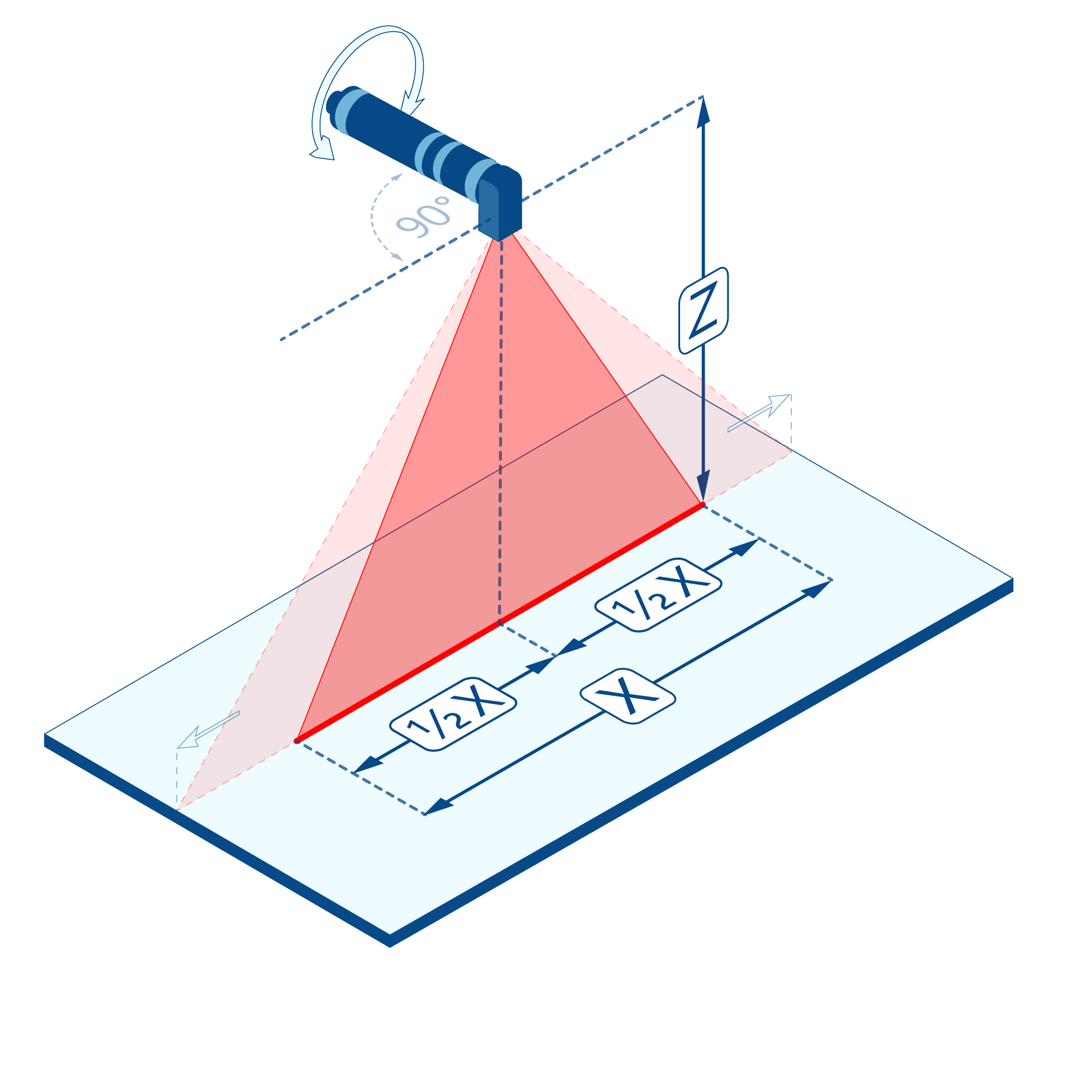

A deflection optic is used to look around the corner. At Z-LASER, we use angular optics in combination with lasers but we don’t look around the corner, we “laser” around it, that means: the laser beam is deflected by 90° using a small mirror in order to get the projection to where it is needed.

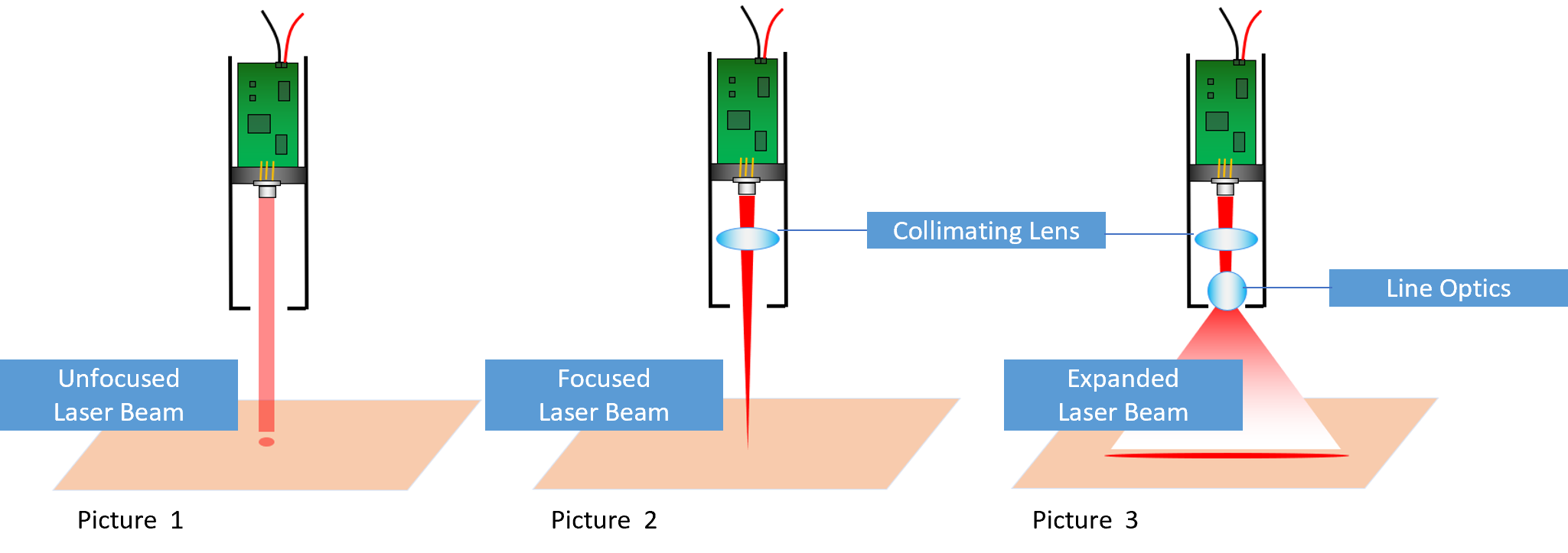

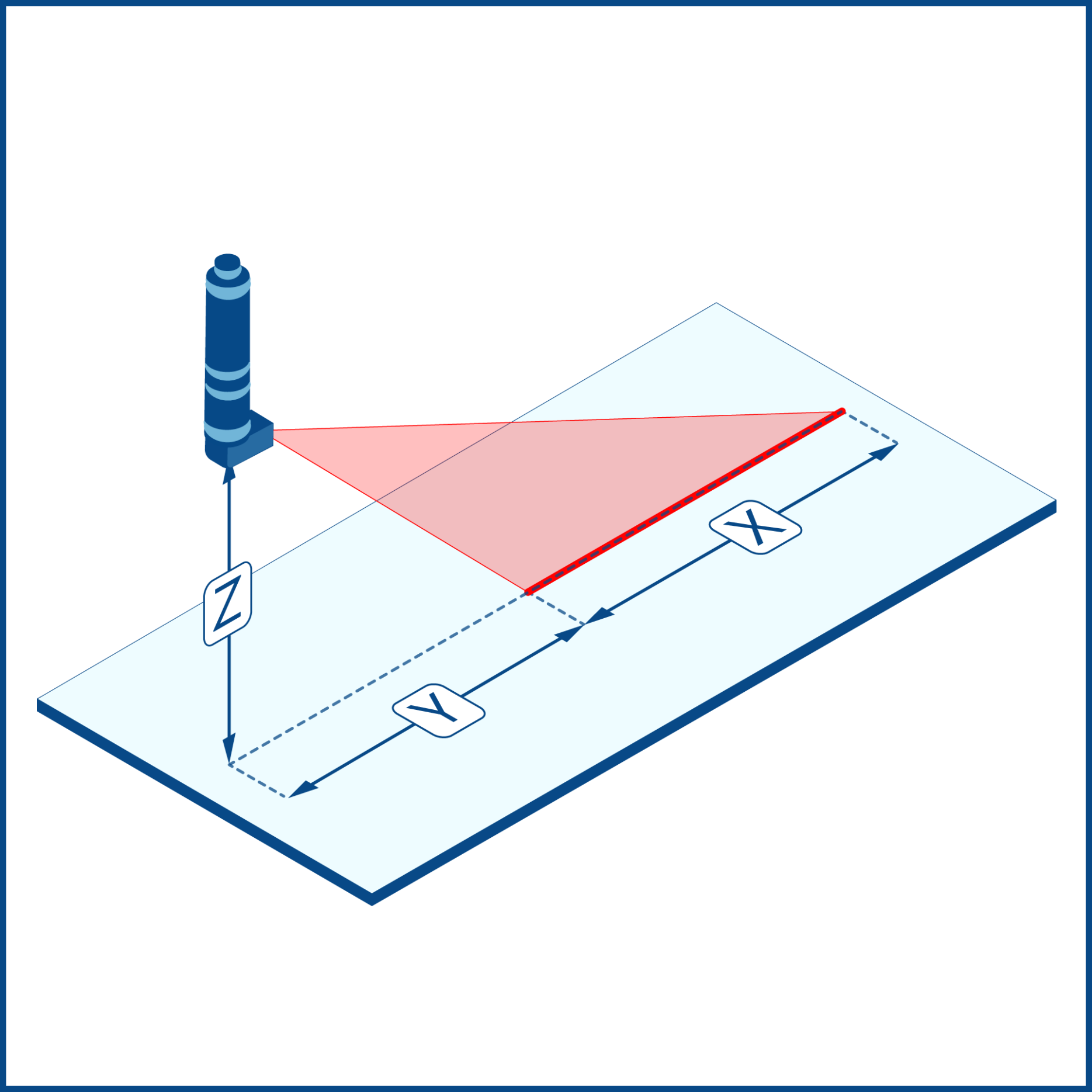

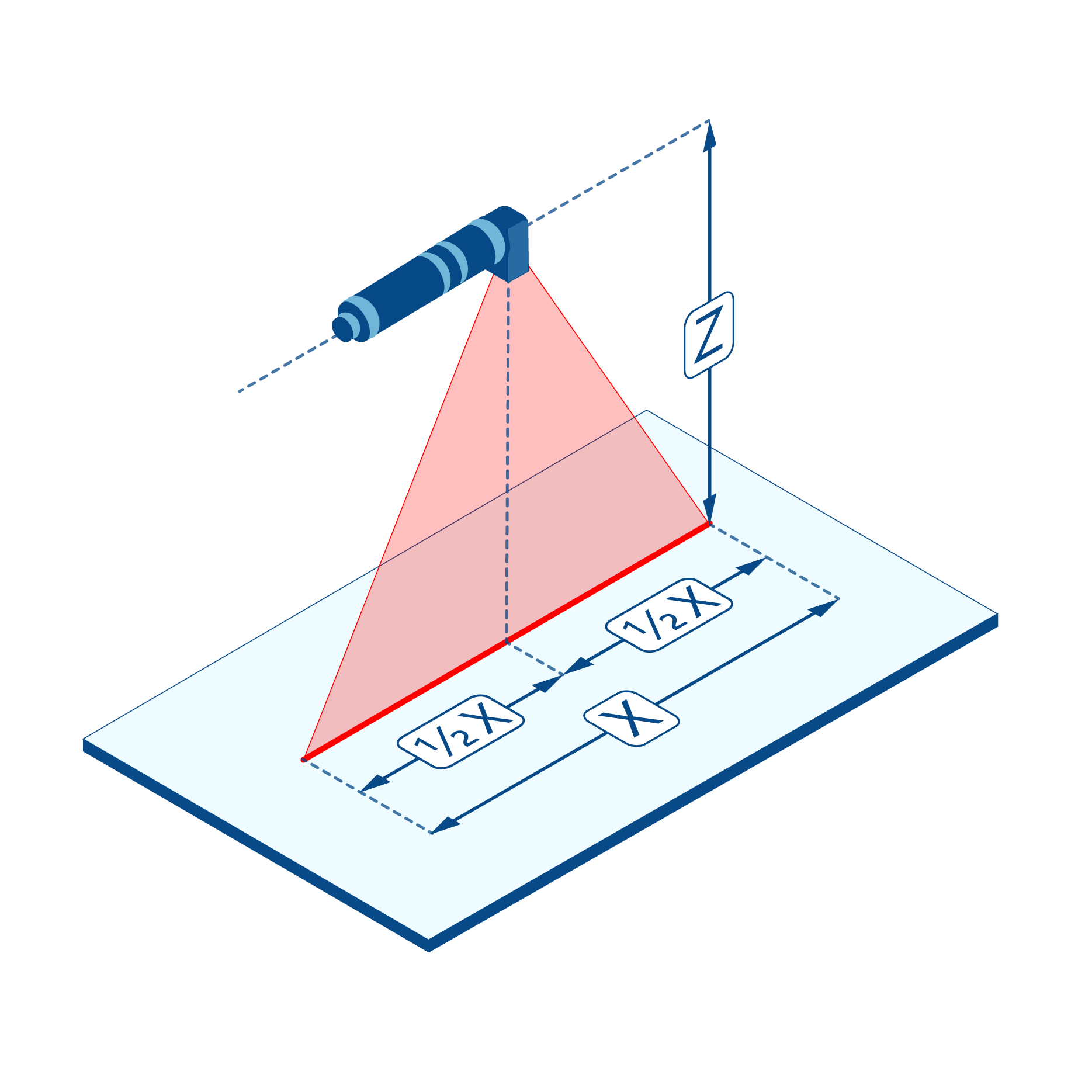

In order to understand why line lasers with angular optics are needed, you have to consider the principle of the line laser:

The laser beam is focused (Figure 2) and then expanded using line optics (Figure 3).

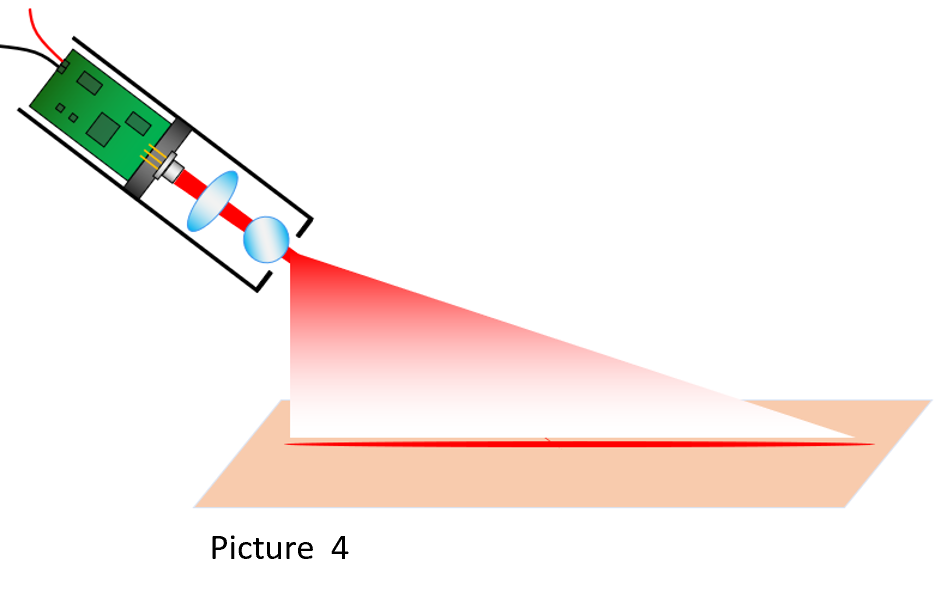

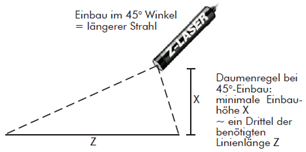

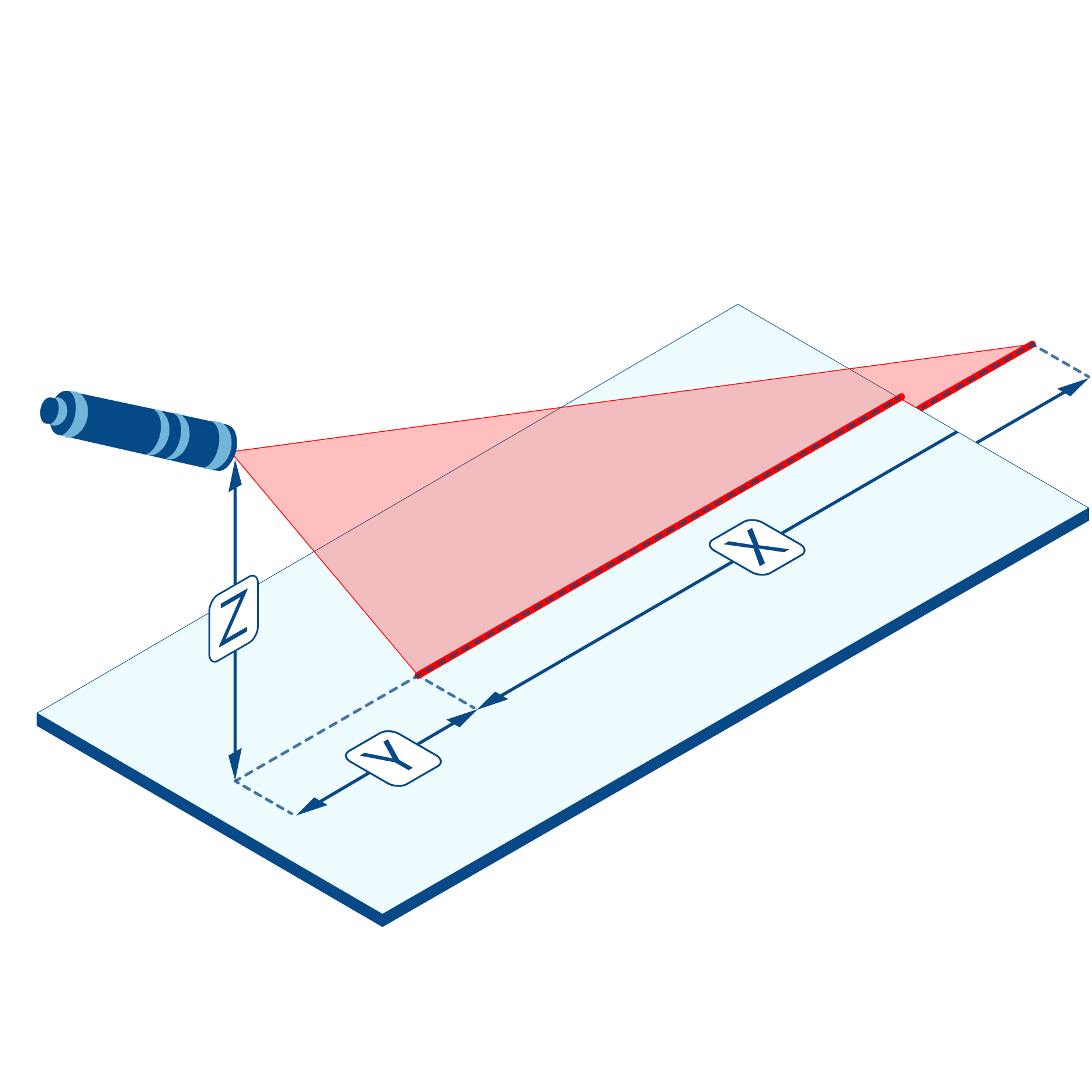

In order to get a long line it’s best to tilt the laser towards the projection plane (Figure 4) and maintain an optimum installation height of about 1/3 of the required line length.

This has proven to be a rule of thumb – but it is not technically possible with every application. Typical anti-examples are rip cut circular saws, press brakes or guillotine shears – all machines in which the material is fixed with a pressure beam, e.g. of sheet metal. A line laser cannot be mounted above the processing table here, as with a standard circular saw.

Due to the significantly larger dimensions of a laser housing in the past there were problems to integrate lasers into a machine housing. Until the year 2000 we produced helium-neon gas tube lasers with a diameter of 55 mm and a length of 670 mm! An installation in an angle? Impossible! Vertical or horizontal installation? It fits. For that reasons line lasers with deflection optics were developed.

Various combinations emerged during the last years, depending on the installation position of the different applications.

However, the most common variant remains the vertical installation with beam exit at the bottom. By using diodes as laser source the laser dimensions became smaller and smaller: Instead of the large Ø55mm HeNe lasers Ø40mm diode lasers with built-in power supply were developed: At first ZP (todays: ZPT-F), afterwards the ZR series and finally the “green runner”, our ZRG-F series.

By using diodes as laser source the laser dimensions became smaller and smaller: Instead of the large Ø55mm HeNe lasers Ø40mm diode lasers with built-in power supply were developed: At first ZP (todays: ZPT-F), afterwards the ZR series and finally the “green runner”, our ZRG-F series. With low installation heights you need sophisticated optics to achieve a line with nearly homogeneous intensity distribution. With only 200-500mm height above the table it’s not possible to project a nice even line with a length of >3.000mm – especially no with standard line optics like cylindrical glass rods.

We received more and more requests for an affordable line laser for low mounting heights (German word “Tiefeinstrahler”). In 2017 we launched the solution for these applications: the sophisticated lhi90a line optics which are available in different ZM18 versions (red and better visible green).

These are so small (ø20mm x max 108 mm) that they fit to any installation space, despite the required installation position in an angle of approx. 45°:

Angle optics thus become obsolete. Additionally more and more customers prefer to operate the laser directly with the machine (5-30VDC).

For all customers still needing a laser with deflection optics we offer various ZM18-L90 models

Z-LASER GmbH

Merzhauser Str. 134

D-79100 Freiburg

Tel: +49 761 296 44-44

Fax: +49 761 296 44-55

e-Mail: [email protected]