Sie sehen gerade einen Platzhalterinhalt von Standard. Um auf den eigentlichen Inhalt zuzugreifen, klicken Sie auf den Button unten. Bitte beachten Sie, dass dabei Daten an Drittanbieter weitergegeben werden.

Applications in the fields of insulation, bodywork, interior, and logistics

Assembly

Display & control

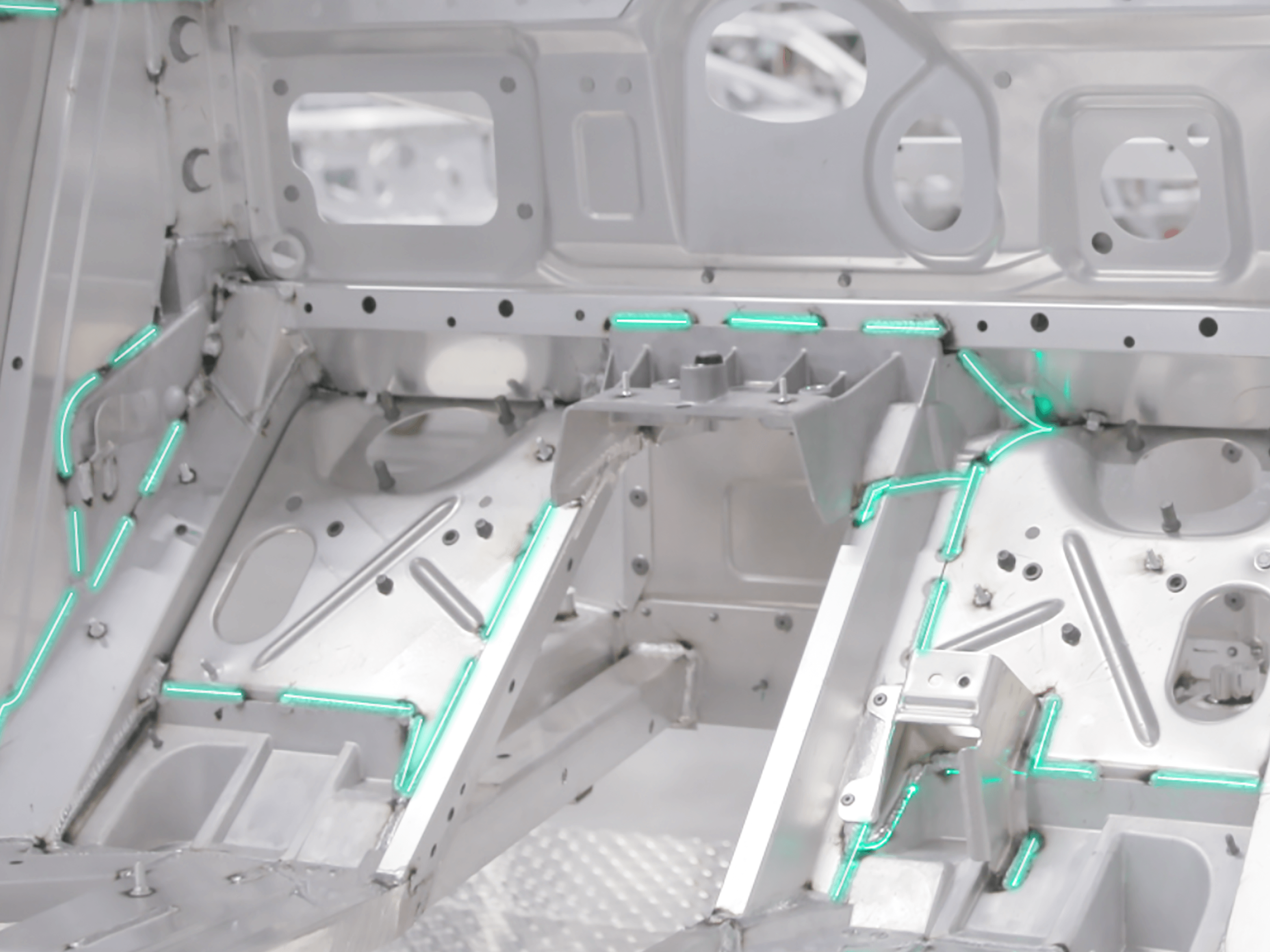

Car interiors often involve complex and manual assembly, for example on car doors. Laser projectors guide the worker visually through the manufacturing process here: They show how many of which components should be taken from where, and where they should be fitted. This significantly speeds up processes such as routing cables. What’s more, instruction texts and critical points or error markings can be shown. This means less training time is required while at the same time strengthening quality control. Using a laser projector to display a red area can help to ensure the safety of the entire manufacturing process.

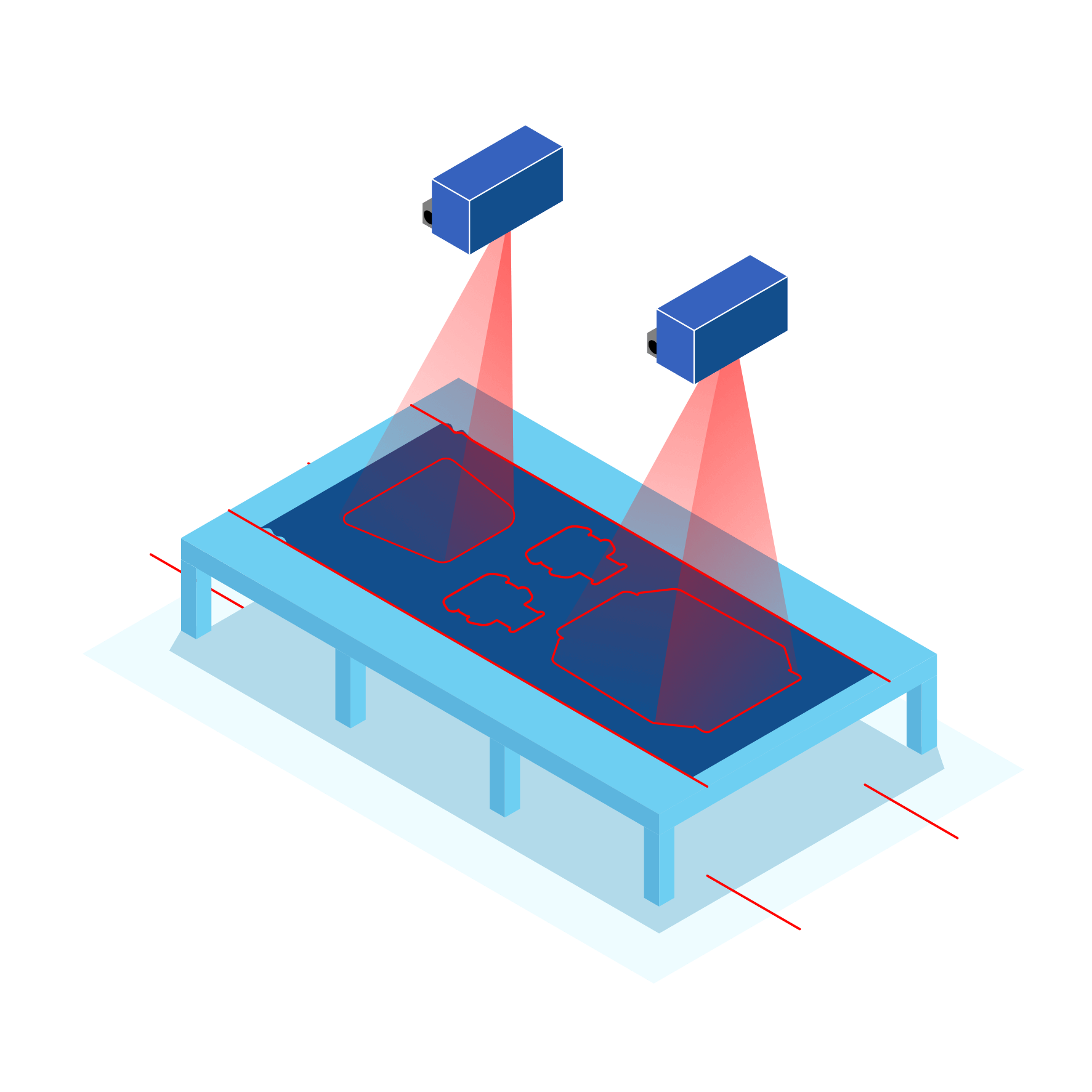

Caravan construction

Wall and floor elements are produced using a sandwich design in caravan and mobile home construction. The laser projectors serve to position assembly elements such as fasteners, struts, and electrical cabling. Ideally, the individual assembly elements are on separate graphic layers so that they can be projected in succession. Generally, two laser projectors with a green beam source are required for each work table.

Welding

Welding steel components requires great accuracy when it comes to bodywork. Using template projection on the workpiece makes it possible to check the accuracy of the actual welding joints. The same applies for welding points, which also need to be checked for completeness and correct positioning.

Sound absorption mats

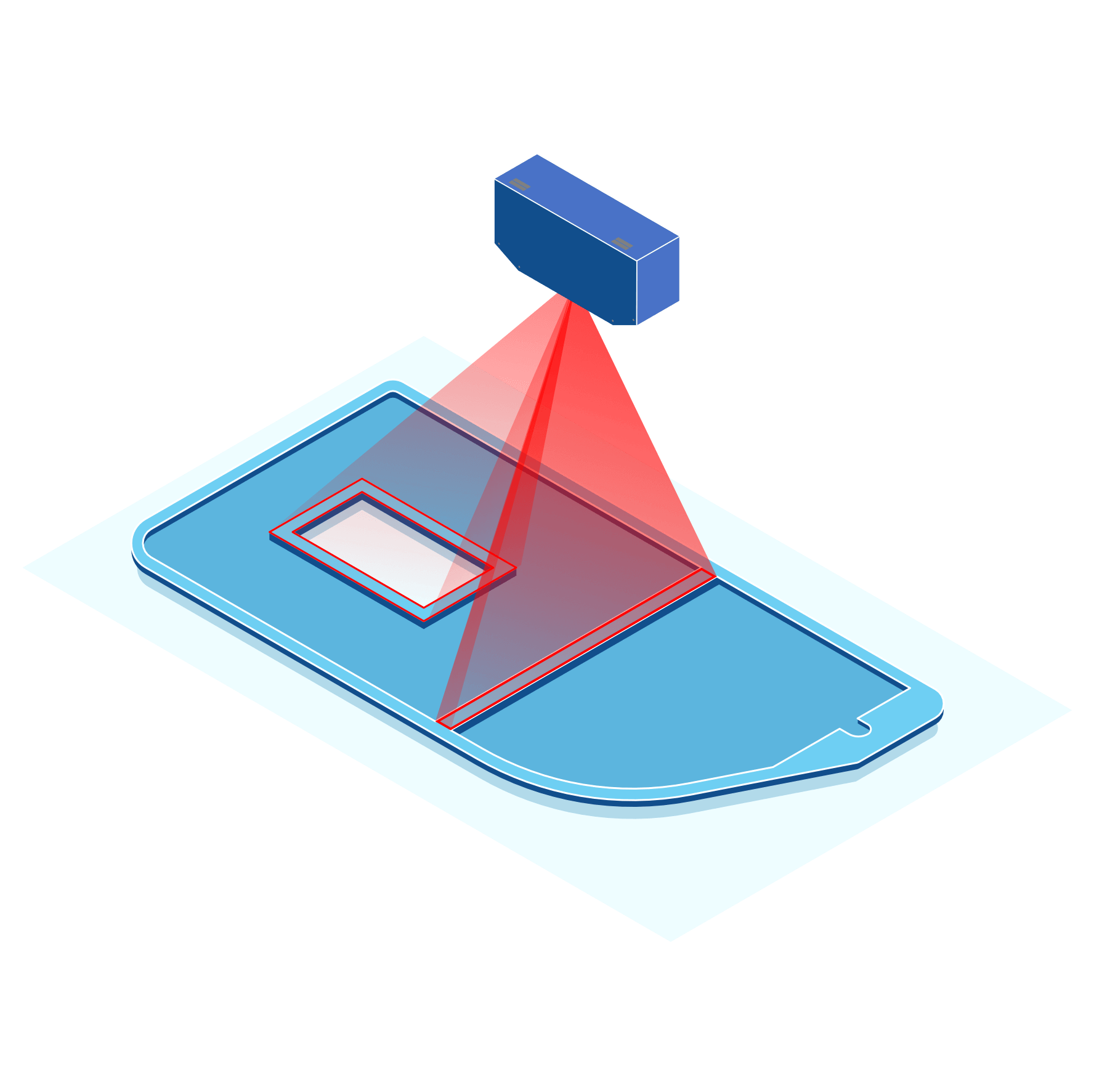

In order to avoid irritating vibrations in the vehicle, sound absorption mats are fitted in areas such as the trunk or fuel tank. To position these mats exactly, laser projectors are used which display the outlines of the mats. This makes it easier to align and then glue the mats.

Seat coverings

The high-quality fabric and leather parts are cut on lay tables, where a laser line is used for exactly aligning the pieces. A cross laser can also be used for checkered fabrics. When sewing the pieces, a line laser shows where the seams are to be placed. In the last work step, simple dot lasers help to fit the seat cover perfectly onto the car seat by highlighting curved seams or the seam “corners”.

Windshield mounting

When manually gluing the windshield, the swelling tape and glue line have to be attached within a specific area. For optical reasons, markings on the windshield are increasingly avoided. The projection of the target contours for the swelling tape and glue line on the windshield provides the fitter with a simple and effective aid. What’s more, laser projection dispenses with the need for using cumbersome and expensive templates.

Roof liner

During pre-assembly of the roof liner, retaining clips and the cable set for the interior lighting need to be fitted in the right position. Here, the laser projector shows their exact position on the underside of the roof liner, making assembly easier. Either 3D contours can be used or the individual positions can be taught once with the projector and reproduced later.

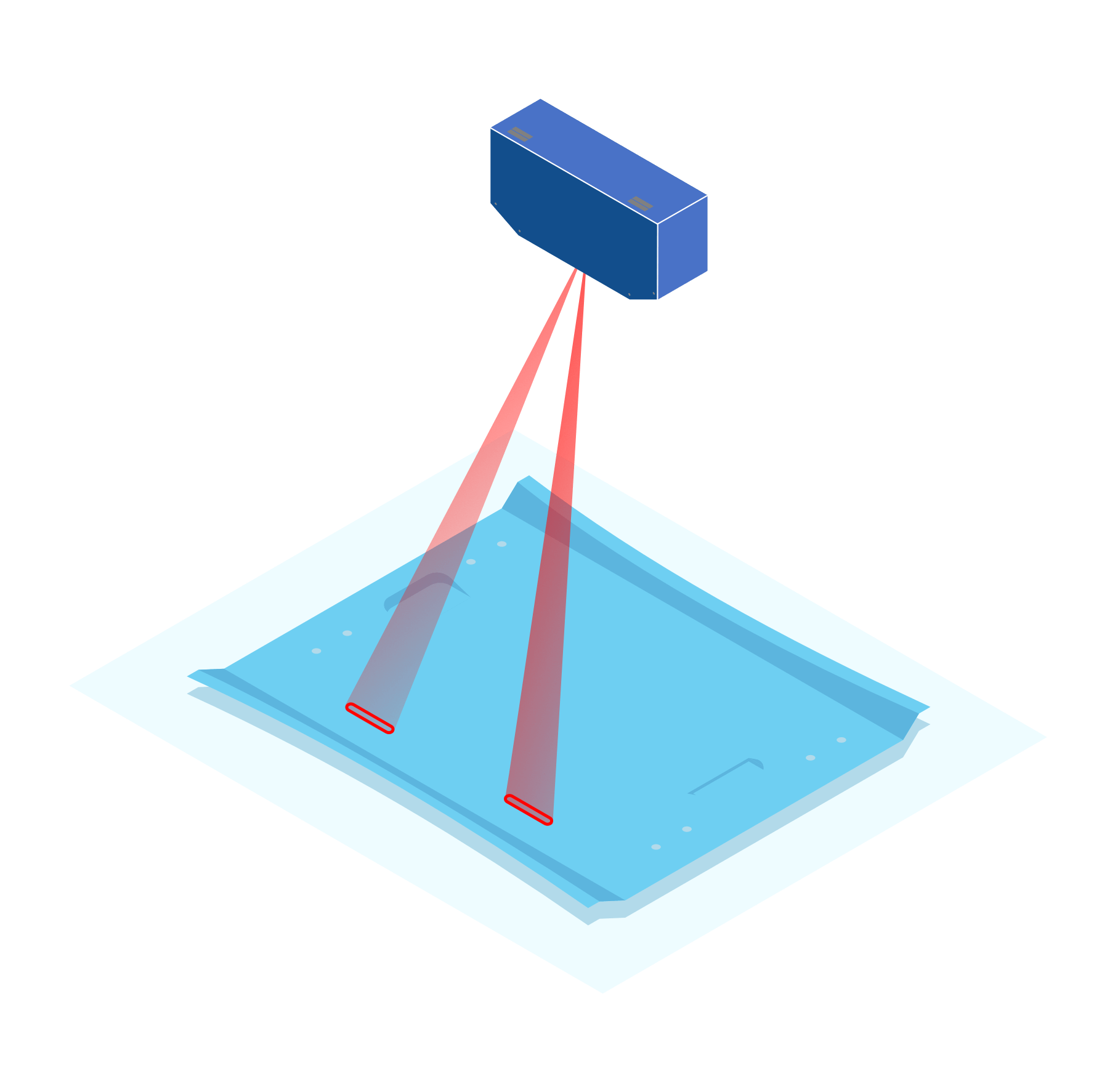

Blanking pallet positioning

With the help of laser projection, the mounting position of the pins is projected onto blanking pallets. The punched or pressed forms are then conveyed onto the pinned blanking pallets via a chute. The laser projection keeps the preparation time as brief as possible and the whole setup time is shortened. This does away with the arduous task of manually measuring and aligning the pallets during production.

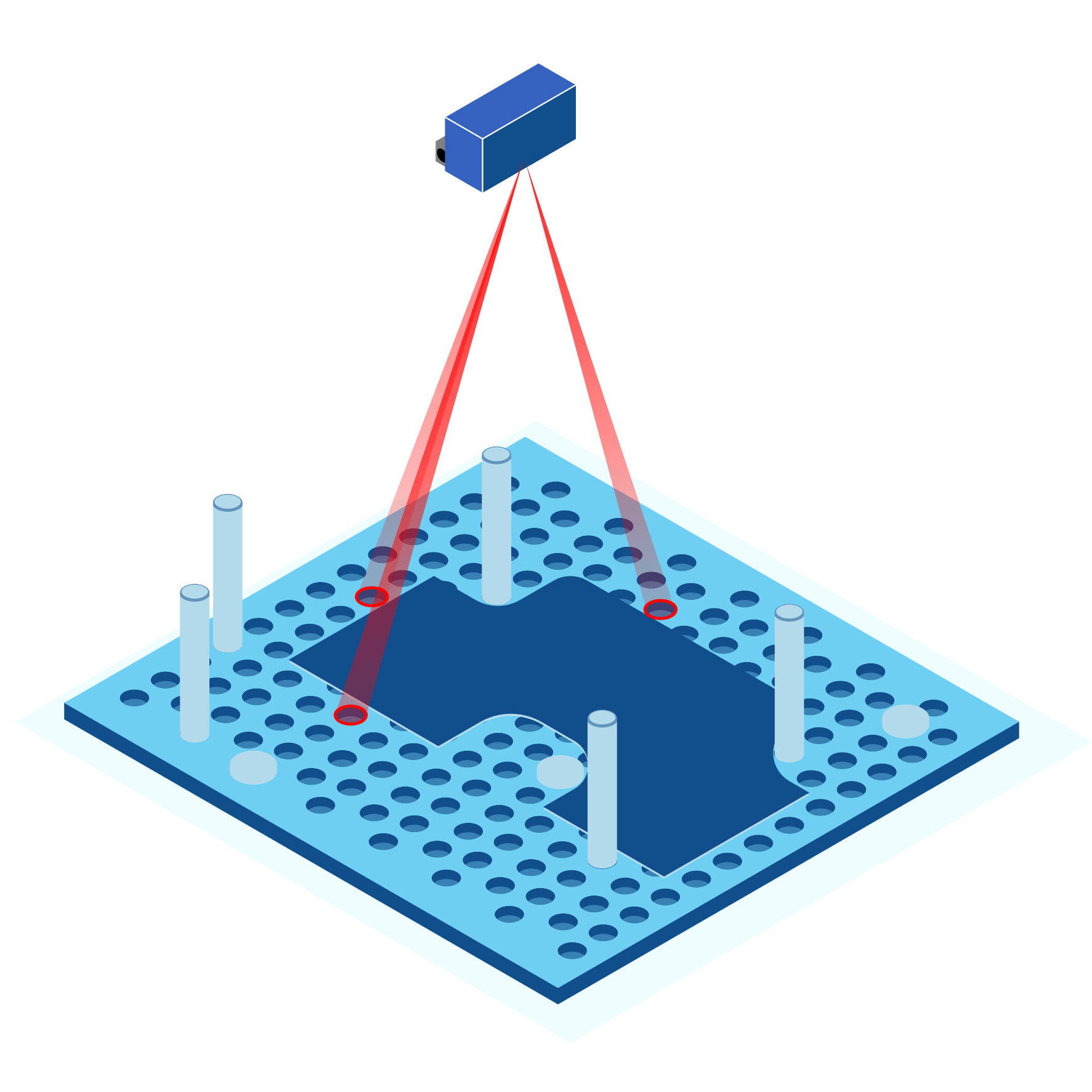

Logistics

When picking spare parts, it must be ensured that no incorrect parts are dispatched. Despite displaying the picking position on a monitor, a lack of concentration or tiredness on the part of the employee can result in incorrect deliveries. Using laser projectors enables 100% picking quality, as the spare part to be picked is uniquely marked. The visual assistance also enables greater flexibility in deploying staff.

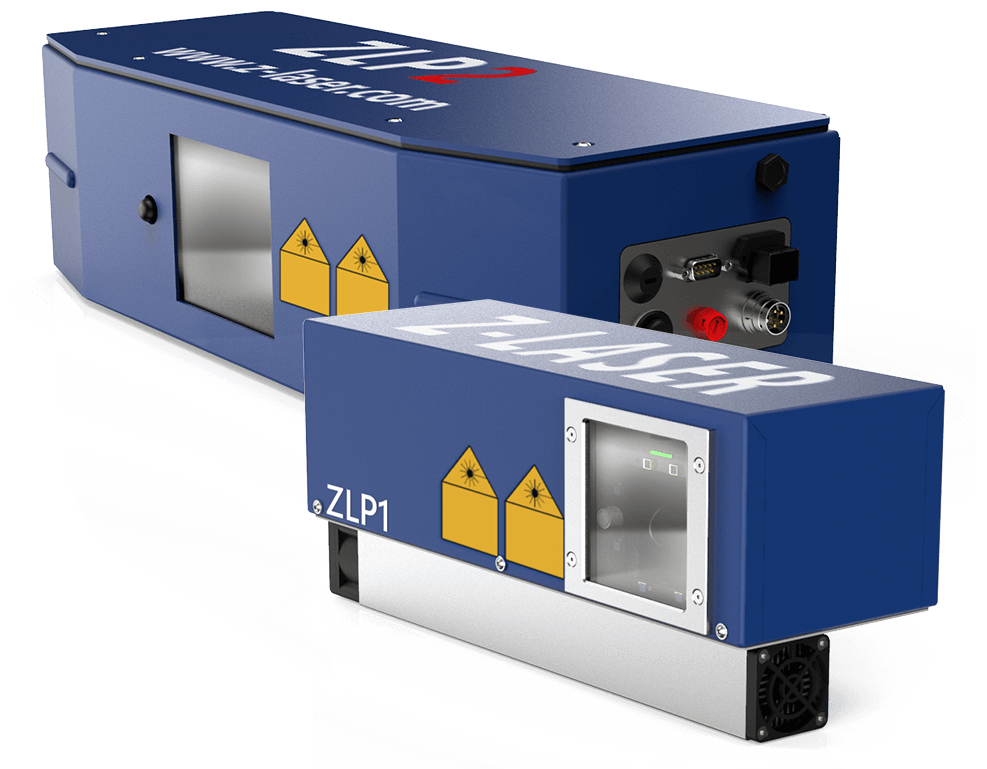

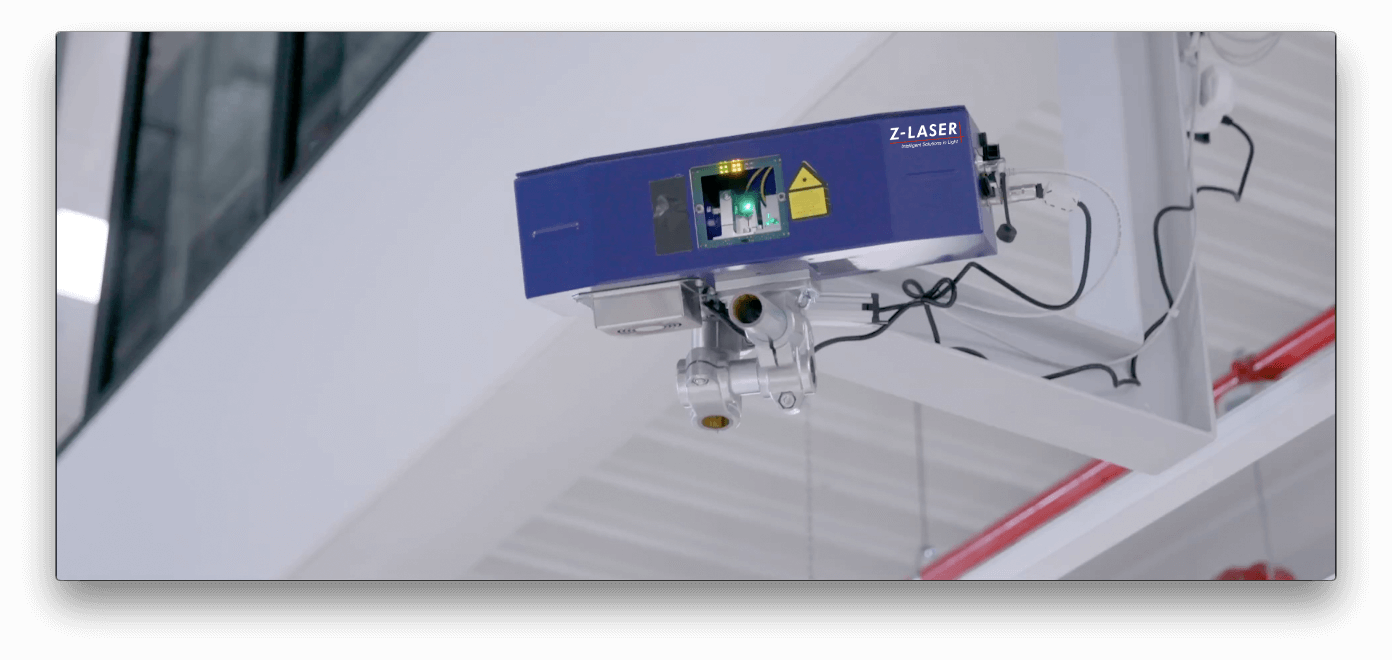

ZLP Laser Family

The powerful laser projectors for optical positioning systems