635 nm

-

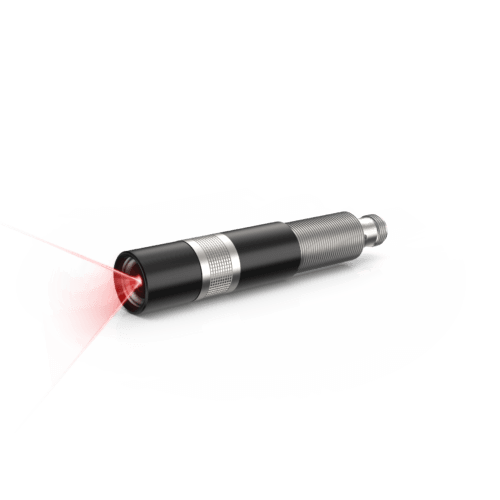

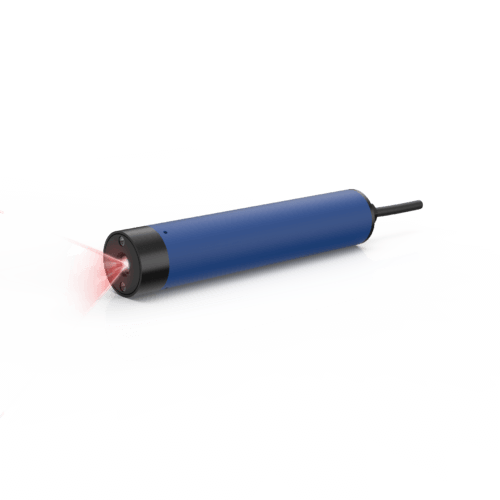

The high-precision laser module

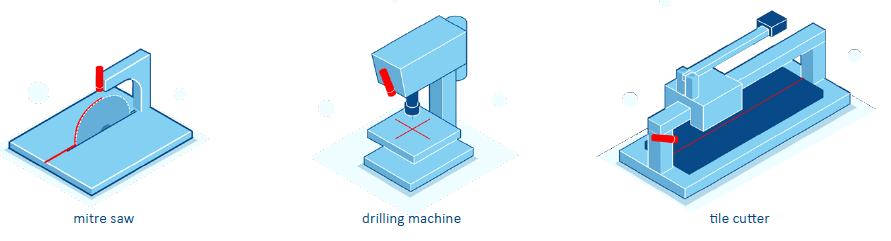

The laser module ZX20 sets new standards for machine vision illumination due to its automated production in which all optical components are aligned by a high-accurracy robot. The ZX-laer impresses with precision. The Borsesight error is less than 0.8 mrad. The user can choose from IR, red, green, or blue wavelengths depending on the application and material to be inspected. The right working distance can easily be adjusted with the tool-free manual focus option. The ZX20 with its industrial-suited design and stable performance works perfectly as an integrated module in machine vision aplications, sensors, or processing machines.

-

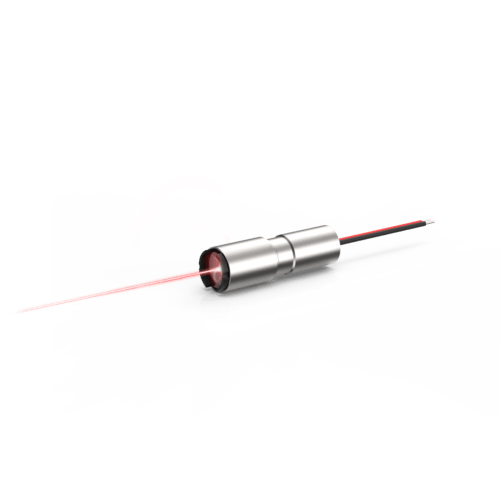

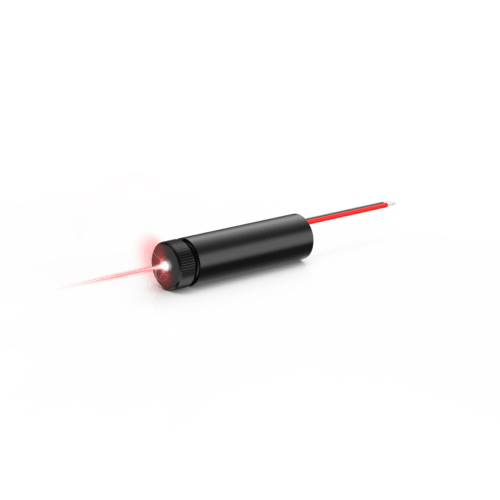

Small size, great performance

The ZX-laser series offers diverse, application specific customization possibilities. The user can choose from violett to infrared wavelengths depending on the application and material to be inspected. The focusing optics achieves a boresight of less than 0.8 mRad. The industrial-suited design along with stable performance works perfectly as an integrated module in machine vision applications, sensors or processing machines. The laser module contains no driver electronics (ZX10-ND) and is therefore ideally suited for OEM applications. Upon request, licensing and integration of the Z-LASER electronics can be provided (ZX10-LD).

-

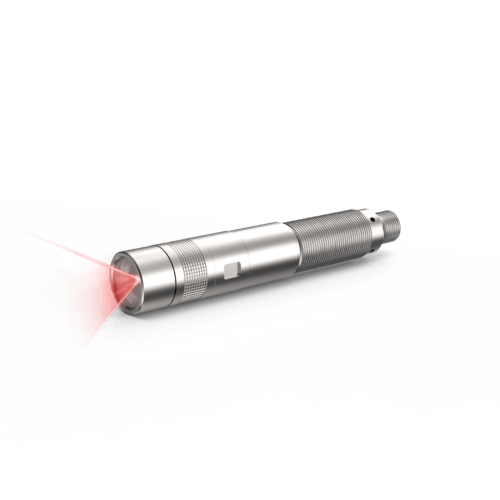

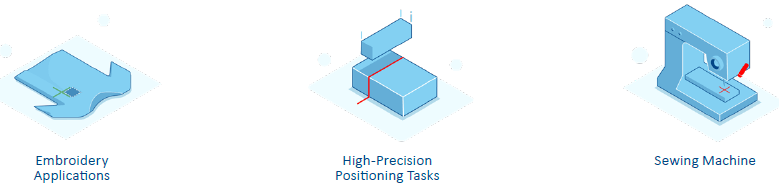

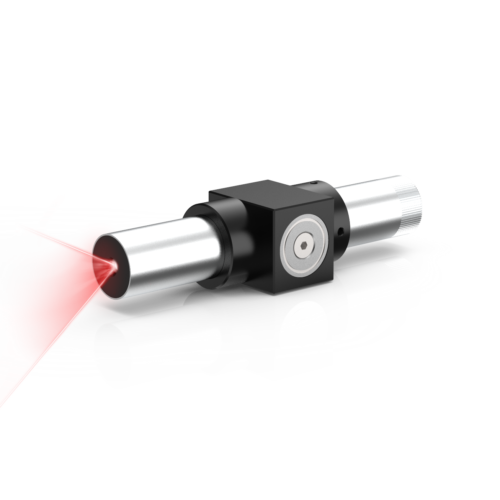

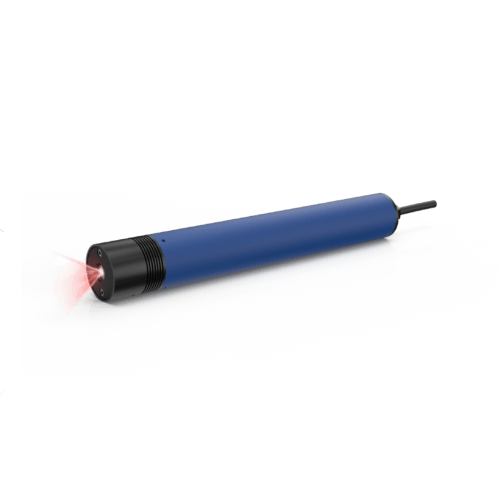

Small but powerful

Thanks to automated production processes in which all optical components are aligned with a 14-axis robot, the ZXS laser series sets new standards for illumination in machine vision applications. With its boresight error of less than 0.8 mrad, the ZXS laser is one of the most accurate lasers on the market. Its remote electronics make the laser module flexible for mounting. On request, an OEM variant can be offered in which, for example, the electronics can be completely integrated into your own board.

-

The precise laser module

Thanks to an automated production process in which all optical components are aligned with the help of a 14-axis robot, the ZX20 laser series sets new standards for lighting in machine vision applications. With a boresight error of less than 0.8 mrad, the ZX laser is one of the most accurate lasers on the market. Depending on the application and the material to be tested, the user can choose between IR, red, green, or blue wavelengths. The tool-free, manual focus option allows the user to easily adjust the projection according to the working distance. Its industrial grade laser design, along with consistent performance make this laser perfect for harsh environments. It can be used in complex machine vision setups, in sensors, and can even be integrated into sturdy processing machines such as saws. -

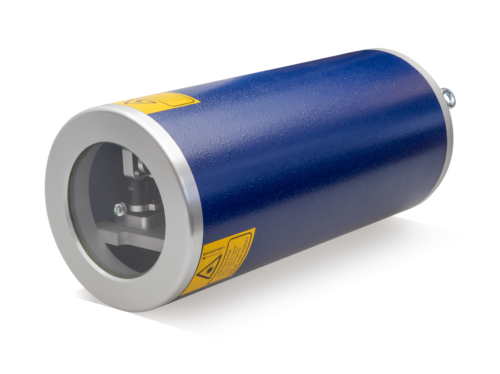

The laser-based belt drive alignment tool

The Belt Aligner is a tool that has proven its worth a thousand times over for aligning drive wheels. It is based on a battery driven line laser from the ZAT series. It sits compactly and perfectly aligned in a specially designed mounting block. The red laser line runs exactly parallel to the magnetic contact surface. With the help of target markers, drive wheels and impellers can be safely aligned in an idle state. Scope of supply- Battery operated line laser in magnetic bracket

- 1pc. levelling plate, magnetic

- 4 pcs. measuring markers, magnetic, Aluminium

- 1 pc. battery (AA)

- Packed in a robust plastic case

-

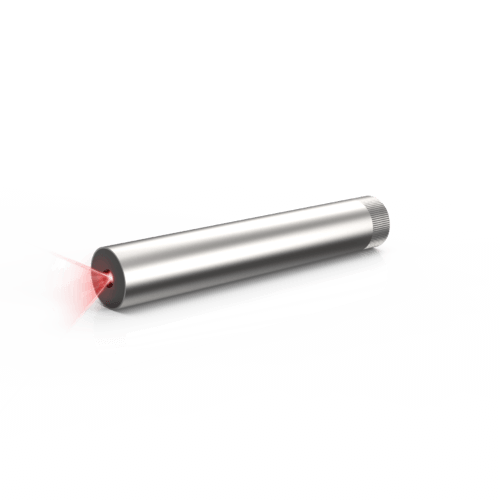

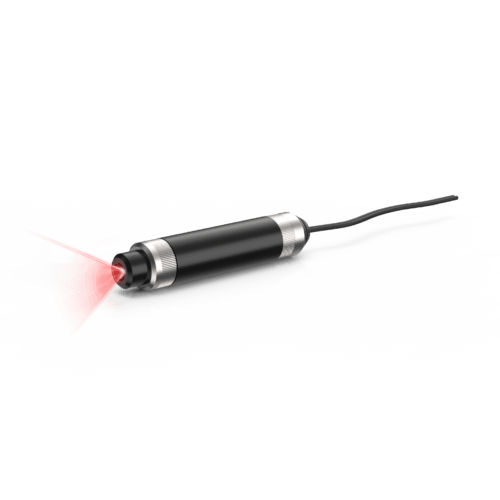

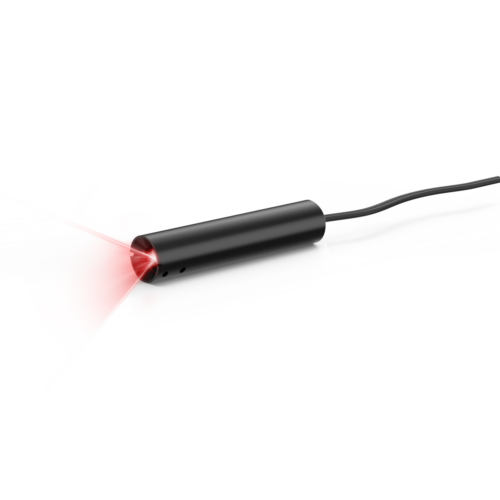

Small manual focus dot laser

This small dot laser (with a diameter of just Ø 11 mm) is ideal for any positioning task, as it can be focused at site for any distance. The wavelength of 635 nm (red) is perfectly visible on most materials. It is often used in the wood, stone, textile, metal, tire, concrete and food industries