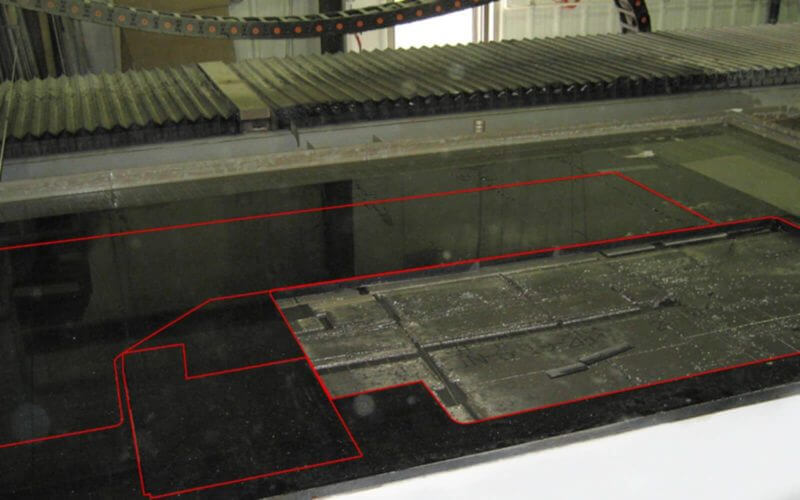

Today, modern furniture includes vanity tables, kitchen countertops, stairs, etc., made of marble, granite, hard glass, and special plastic materials. Production is carried out in CNC processing centres. Special vacuum suction devices fix the material for processing. Lasers are used to optimally place the suction cups so they are not damaged during processing. After setting the cups, laser lines indicate the contours to be cut out. Everything is positioned in such a way that the milling cutter cannot damage the suction devices while the work is being carried out.

While aligning the workpiece, the laser facilitates the optimum utilization of the material by displaying the contours of the finished workpiece on the stone. Production staff can then align the material so that any defects in the grain are taken into account.

The superior, freely scalable LPM laser projection software supports the most widely used CNC formats as well as DXF. This allows contours to be transferred directly to the laser via the machine control. If the sucker height or material thickness happens to be included in the source file, the projection is automatically corrected and set to the correct height.

Special Uses:

- Good visibility of laser projections and compliance with laser class standards

- High IP protection against dust and moisture

- Distortion-free projections, even on large work surfaces

Advantages:

- Optimal use of material

- Increased product quality

- Reduction of material fitting time

- Swift and accurate positioning of suction cups

- No damage to suction cups during the cutting process

Extension

- Manual Nesting (DXF Import and DXF Changer)

- Polling

A clear and simple interface for the transfer of data from higher-level control systems is the polling module. The geometry to be projected is written as a file. LPM automatically opens and projects this file. This makes it possible to avoid errors and speed up workflow.

Communication

A connection to the laser projector can be achieved via different interfaces:

- Serial (RS 232, optical fiber, RS485)

- Network (IPX / SPX, TCP / IP)

Each LPM session can control up to 16 projectors; in a company network, an almost unlimited number of LPM processes can be addressed.

Note for Machine Manufacturers

For optimal connection to your machine’s controls, please request our CNC control data import filters.

- FANUC G1x series

- SIN 840 D

- OSAI G10

- NUM 750 and higher

- Others

Recommended Product: LP-HFD2