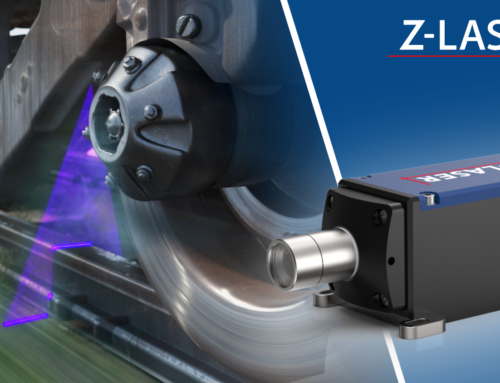

Before and after the press shop phase–in the automotive industry as well as in many other metal and sheet metal processing applications, inspection systems check the metal surfaces for proper shape, inconsistencies, or any damage before they are polished, primed, or anodized. In these cases, optical inspection methods that utilize the structured light from lasers are particularly suitable.

Special Uses:

- High-precision projection of structured laser light in the form of straight lines, grids, circles, or point clouds

- High light intensity for large work spaces, for instance, in the blue wavelength range

- Lightweight construction, such as for easy affixing of arms on a robot

Advantages:

- Fast and flexible measurement in 2D and 3D

- Non-contact and wear-free measuring systems

- High production quality and productivity with lower costs due to a reduction of waste

Recommended Product: LP-HFD2