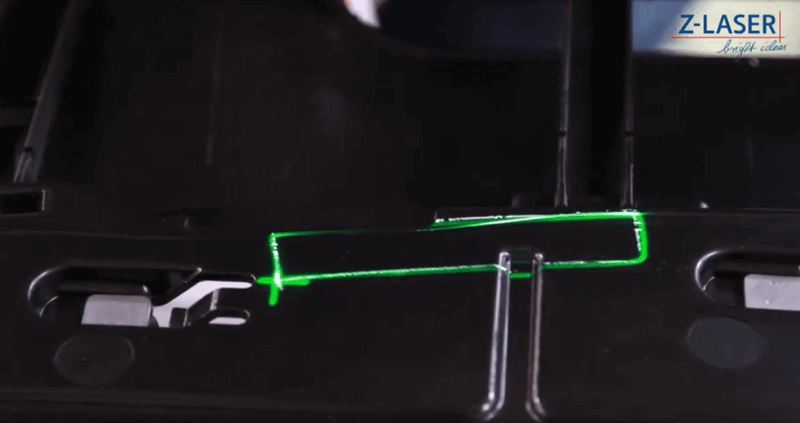

The ZLP1 in use at Mayer GmbH, Laichingen and SKS Automotive in Mosbach, respectively

Mayer GmbH from Laichingen, founded in 1973, now employs 120 people in plastics technology and mould making. As a long-standing supplier to the automotive industry, the company also supplies refined plastic parts to its customers and relies on highly qualified partners such as SKS Automotive GmbH from Mosbach.

At SKS Automotive, the parts supplied by Mayer GmbH are painted, chrome-plated, refined and further processed on request. An important product for both companies is a spoiler, which is manufactured in the Mayer factory and then further processed at SKS Automotive. In this context, Mayer GmbH decided to optimize the production process for the roof edge spoiler together with SKS Automotive.

A previously time-consuming work step was the precise fitting of the roof edge spoiler with a total of 5 adhesive strips. These must be applied manually to the exact positions provided for this purpose. Previously, this was done using templates in which the adhesive positions were left blank and the employees knew where the adhesive strips were to be applied. The shift managers had to regularly check the position and condition of the stencils in order to avoid the risk of complete batches being glued inaccurately. This repeatedly resulted in inaccuracies, as the stencils shifted or worn out over time.

This process has now been digitized. With the help of the ZLP1 laser projector from Z-LASER, the exact adhesive positions are projected onto the workpiece and always show the employees the correct adhesive position. The green laser line of the ZLP1 offers best visibility, even on black and glossy plastics it is very well recognizable.

The ZLP1 used is controlled via the ZLP Suite software supplied. The contours of the adhesive positions were drawn quickly and easily using the software. The surface of the ZLP Suite was also adapted to customer requirements and is now limited to 5 colour-coordinated buttons. The operation is now also possible for laymen without any problems.

“Without the laser projector, our employees spent just under 5 minutes applying the workpiece and template in the correct position and applying the adhesive strips correctly. Now we only need 1-2 minutes for the same job. That makes an enormous difference at the end of the day,” explains SKS shift manager Patrick Quast.

Would you like to find out more about the ZLP1 laser projector?

We are at your disposal for a non-binding discussion at any time.

Product: ZLP1